578 toilets irregularly working with high cost put our customer in an unsustainable position, both financially and branding-wise. The clogged black water system could not be purified, while our client’s end-users were on-board, why they applied extra pumps to obtain sufficient vacuum in the toilet system.

Caring for their operation, the customer attempted to clear the system chemically with limited results. One technician was contracted to keep the system operational at all times, but this was further complicated, as the system is spread over several square meters and over several floors. The traditional method of rinse would risk pipe fracture, as well as major coating pieces detaching and further blocking the piping system.

An Environmantally Safe Solution

Taking the physical circumstances of possible person or equipment injures into account in case of a leakage, IKM Ocean Team determined to use environmental and harmless chemicals when purifying the system.

More than 85 % Reduction in Maintenance Costs

By identifying the root cause of the problems IKM Ocean Team was able to conduct a proactive maintenance approach, generating a great saving for the costumer. The nine extra pumps were not needed any longer, reducing the related costs. One member of staff were released to prioritize other maintenance jobs without interruptions, as he no longer had to handle ad hoc repairs and continuous de-clogging work of the pipe system.

Furthermore, the costumer experienced a saving in the purchasing and changing of valves. A member of the vessel maintenance crew states:

“We have almost had no clogs in our vacuum pipes after the acid cleaning. What we have seen during the last month is equal to what we had per day before we docked. Our vacuum pumps only operate ¼ of time they did before. – And then it was a really good team on board from IKM Ocean Team. A real satisfying co-operation both internally and with the vessel crew. Huge praise from us.”

Did you know?

- Root cause analysis prevent problems opposed to “putting out fires” at a later stage.

- Our supervisors and specialized technicians are broadly skilled and highly trained, co-operating with in-house expertise in root cause analysis, including chemical cleaning.

- A pro-active maintenance strategy determine root cause failures. Correcting these at early stages saves the company costs and downtime.

Looking to the Future

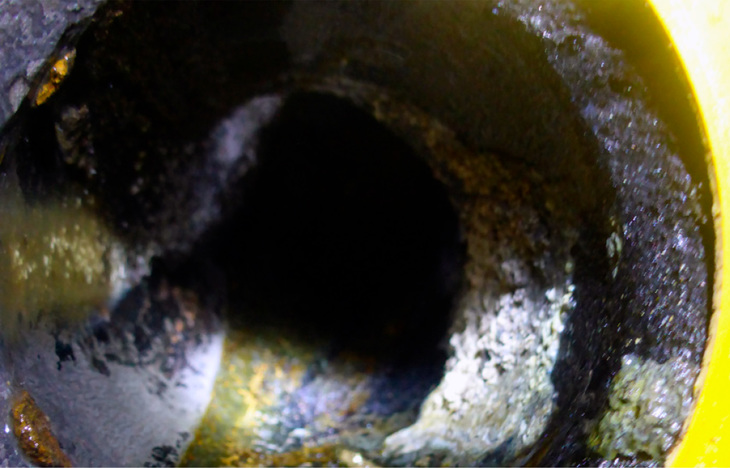

By taking pictures of all ends of the system before and after the purification enabled the costumer to document the appraisal of the system. The documents made it possible for the costumer to assess when the system needs purification next time and accordingly applying a proactive maintenance plan.

Before: Clogged pipes before environmental friendly actions were taken. The passage was decreasing over time.

After: The pipes after the chemical purification were not only cleaner, but it also created a full extent of the opening.