On an oil and gas production platform in Brazil, a problem with the cooling system was observed. Problem was an increased Dp (delta P) above the tubular cooler.

The problem was caused by the fact that the pipes were contaminated with undesirable, harmful substances such as rust, calcium, hydrocarbons, and other organic/inorganic materials. Coatings of such substances have a negative effect on the cooling system, because they reduce the flow and further the decrease in pressure, reduce the transfer of heat, or at worst, causing plugging, corrosion, deformation or leaks.

The customer was aware of the problem, and as an emergency solution, avoiding additional production losses, led the fluid over a reserve heater so as not to stress the defective coolers further. They knew that it would not be a solution for the long haul. The optimal solution would be to have the cooler cleaned as soon as possible, in order to again achieve an acceptable cooling effect.

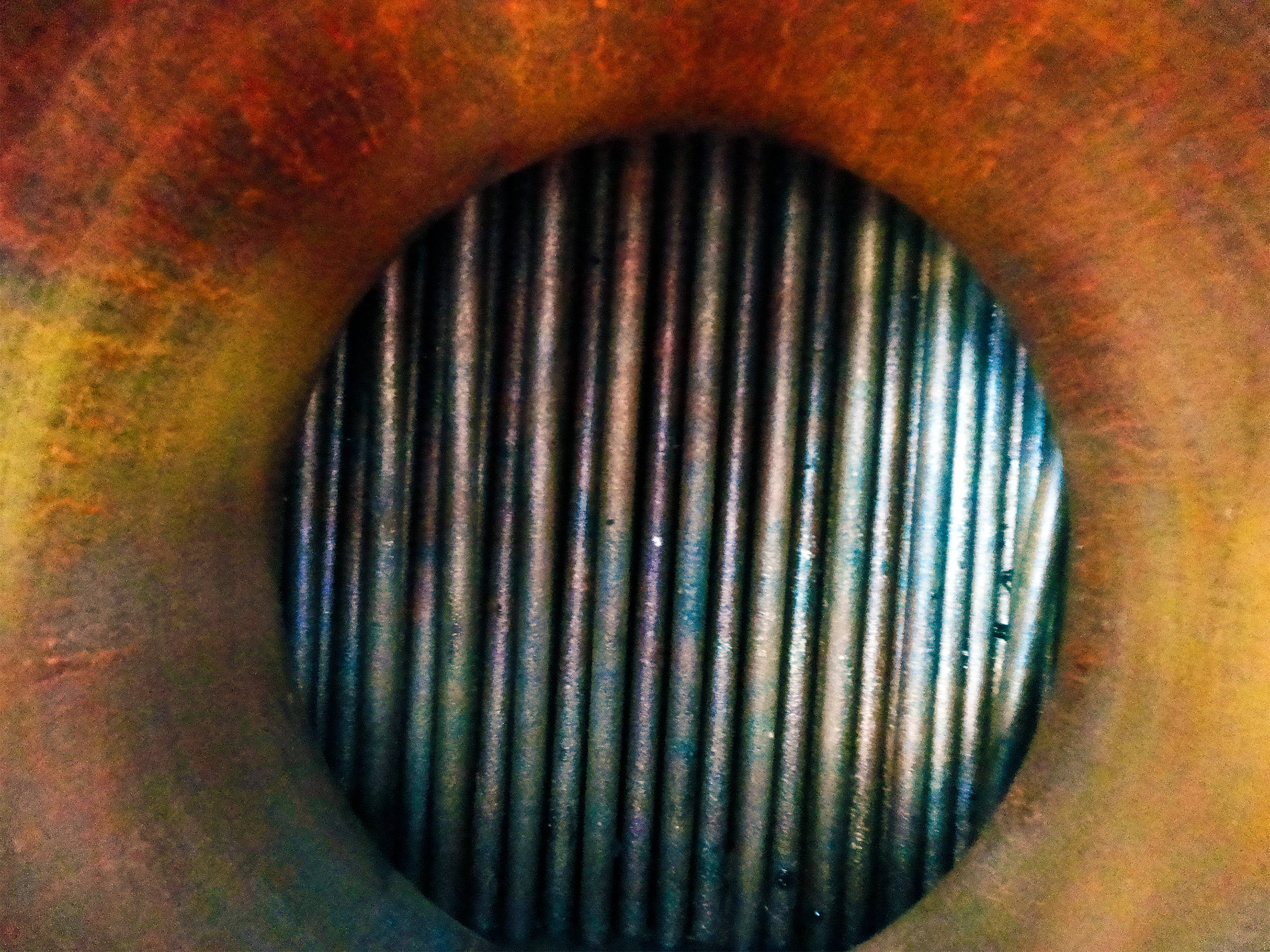

This is how bad the cooler inside looked before the chemical cleaning.

Solution 1:

Purchase of new Coolers

-for a double-digit million sum (DKK).

The cooler was too large and heavy for dismantling and transport to land for cleaning.

The only thing the customer could do was to scrap the heavy coolers and buy a new and lighter version that could replace the old one. Purchasing such a new cooler would cost a double-digit million DKK sum.

Fortunately, the customer knew of IKM Ocean Team and our chemical cleaning method, which would be able to clean the cooling system directly on the oil and gas’s production platform, and would therefore be able to avoid having to purchase a new cooling system, as well as scrapping the old.

IKM Ocean Team’s Solution:

The result clearly shows after chemical cleaning.

Chemical Cleaning of the existing cooler. The customer contacted IKM Ocean Team and explained the problem. IKM Ocean Team had previously solved such tasks and immediately went to Brazil to perform a chemical cleaning of the obstructed cooler.

According to the type plate on the cooler, it could contain 3600 litres, but when IKM Ocean Team filed the chemical, the cooling system could hold 3000 litres. In other words, this missing 600 litres had to be unwanted dirt which had to be removed so that the cooling system could again be able to provide an optimum heat transfer. On the platform, we were very surprised that there was so much dirt in the cooler that it almost corresponded to 16% of the volume in the cooler.

In addition, the Dp pressure of the cooler decreased from 8 bar to 0.4 bar after the chemical cleaning, which is a significant improvement on the cooler, which again provides optimum cooling for the oil and gas wellhead process.