It is all about the environment.

- About safe work environment.

- And about the natural environment.

Legal Handling of NORM Scales

Therefore, our client, one of Northern Europe’s largest energy groups, approaches IKM Ocean Team. One of their offshore facilities needs replacements of components. This means scrapping of water injection pump parts.But; the parts are coated with a hard layer: Does that layer radiate any radioactivity?

It did!

Parts scaled with a NORM layer must legally be cleaned off, before any further cleaning, repair or decommissioning.

Measuring Levels of NORM

The client needs to destruct the parts. Boxes containing the parts arrive at the IKM Ocean Team Group’s premises.

Before approached, the boxes have their level and type of radioactivity measured: In case of gamma rays, the parts are sent off. In this case NORM material radiating beta and alfa rays are cleanable. 'Paul', our IKM Ocean Team NORM specialist, is experienced in volatile measures with the various types of meters, and in their use.

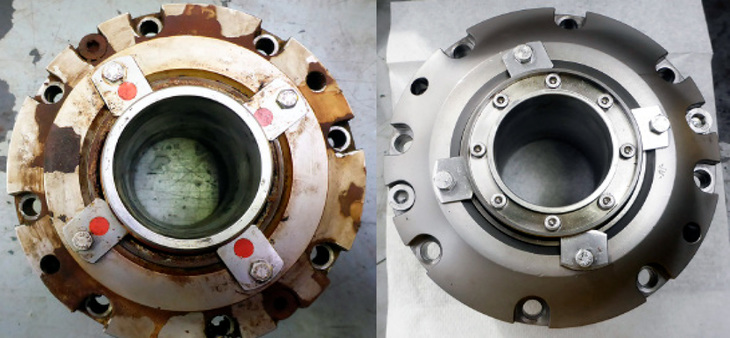

Parts before and after the IKM Ocean Team NORM clean

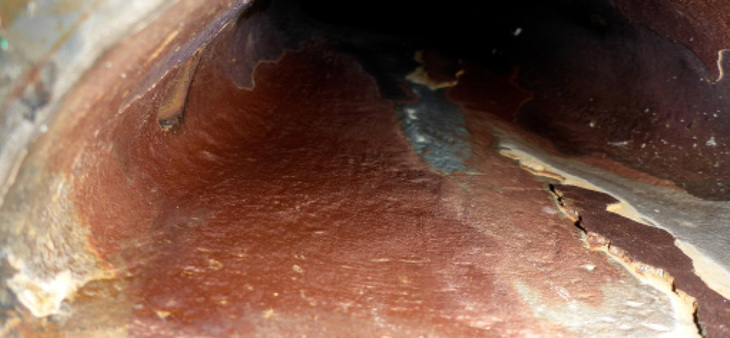

Detail of BaSo4 scales

Hence, he measures on surfaces at defined distances, at the full circumference of the objects, and inside pipes.

Ultra-Sound Cleans NORM Scales

The expected industry method of cleaning NORM scales is ultra-high pressure. IKM Ocean Team uses a three-fold solution with the extra benefit of working in a liquidous phase: Heat, chemistry, and ultra-sound.

Sinking parts into an ultrasonic bath diminishes the dry handling of NORM eluding human contamination while avoiding NORM splashes and aerosols onto the wider environment compared to using ultra-high pressure water.

Besides, ultra-sound, though efficient, never ruins the part material.

Shorter Time and Lesser Space Needed

'Paul', carefully processing the ultrasound cleaning overnight, controls the radiation of the cleaned water injection parts the following day. They must show no fluctuations. Now the parts can be delivered to the client for legal destruction. The entire process proves time and cost efficient compared to the ultra-high pressure cleaning method, supporting our client in their defined success criteria of safety, environmentally friendliness, and efficiency.