When a plate heat exchanger is cut out, it often become an urgent matter to get it back in to production.

Routine Check

Both cut outs on location and the manufacturers routine service check of the their customer’s plate heat exchangers contribute to more cleaning tasks by IKM Ocean Team. Our workshop take care of all leak testing as well as chemical and mechanical cleaning.

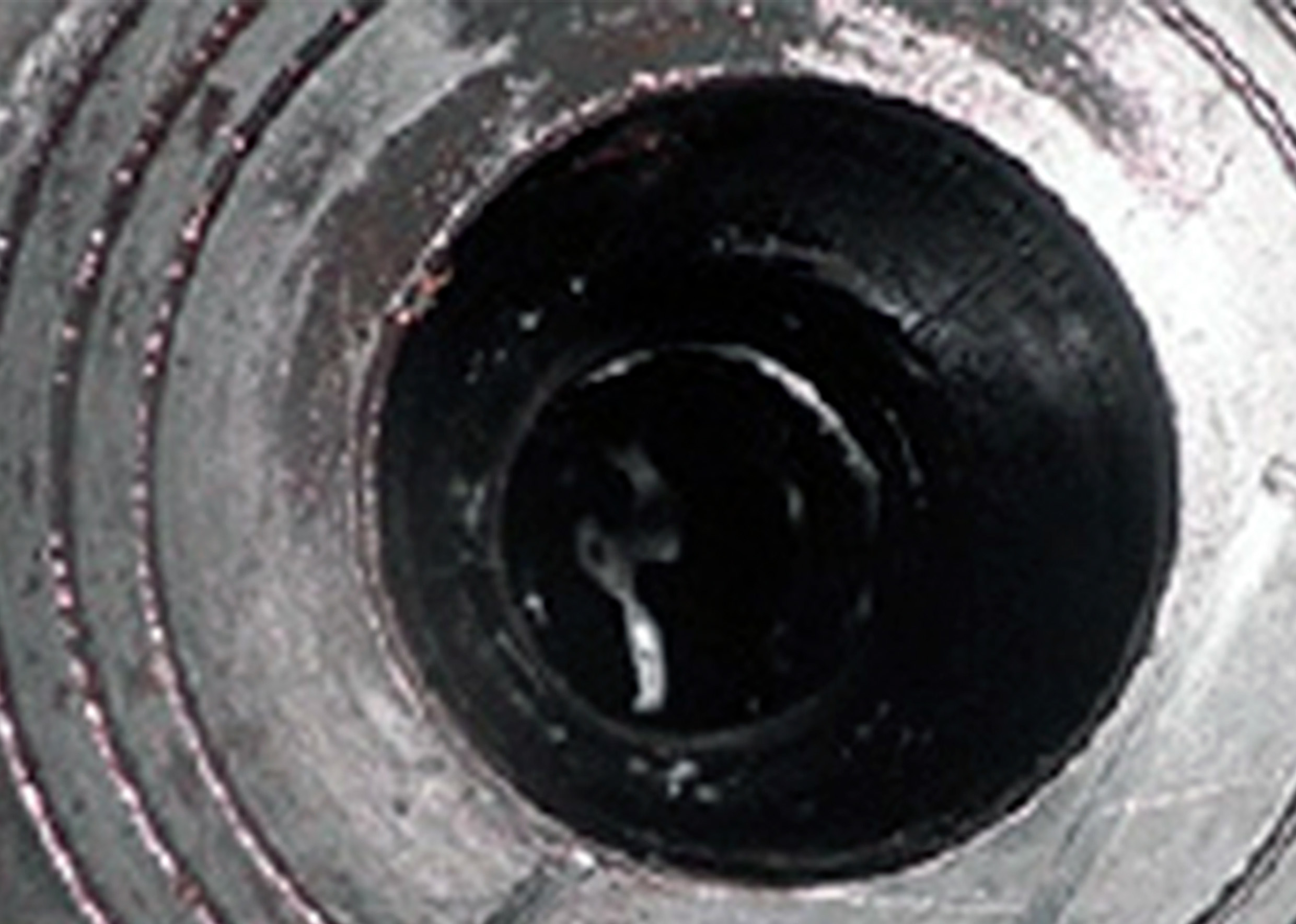

A routine check reveals the need for chemical cleaning.

The result is as a rule a plate heat exchanger with an increased effectivity which has gone from zero to full power.

IKM Ocean Team Welcome Urgent Tasks

Our One-Stop-Shop is always ready when urgent matters occur. The required technicians are flexible 24 hours a day, enabling the possibility to acute purifications on workdays and weekends. Great experience leads to a routine in picking out and mixing the chemical cleansers in a pace that effectively fits our customer’s needs and deadlines.

Conditions before chemical cleaning. Plate heat exchanger strongly affected by mussels, snails and other types of marine fouling.

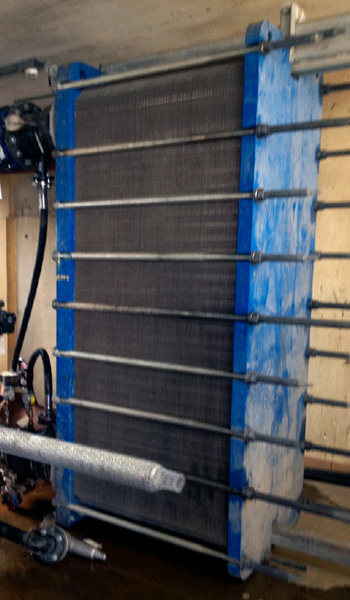

Asset after chemical cleaning, ready for improved production.

The Alternative Calls for a Long-Term Prioritisation

It might be cost effective to order a new heat exchanger instead of cleaning the used one. The time of delivery though, is often long and uncertain. The alternative is for that reason not sustainable when dealing with urgency.

Example of a plate heat exchanger. It uses seawater for cooling of the process water used in production.

The heat exchangers are removed from production in turns and cleaned… saving both time and expenses in relation to the mechanical cleaning method.