Shut down is a costly procedure. Conventional methods for replacing valves require a shutdown. Therefore, our customer, a major player on the Danish offshore continental shelf, has not replaced several valves on the offshore platforms in operation, operating with reduced asset uptime and reduced process productivity.

Prepearing not to shut down, we use an AOGV (Add On Gate Valve) tool . At an initial on-site field survey, we investigate the conditions for best choice of tool and procedure.

The feasibility study establishes the type of AOGV tool and the space requirements for operation of blind plates and bolts.

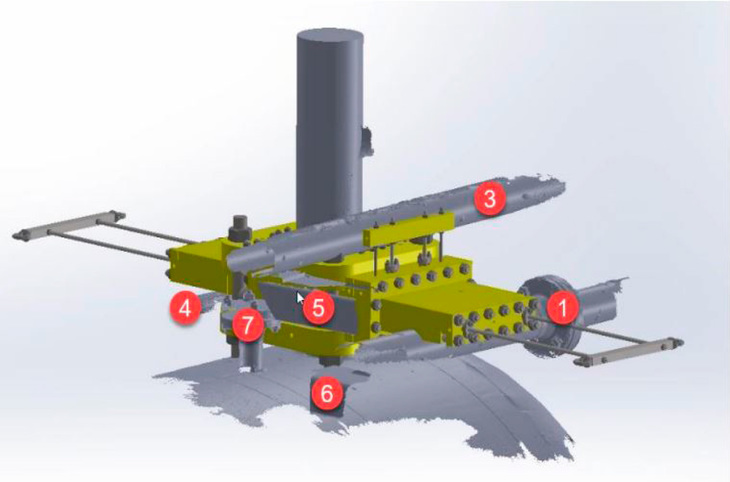

Extract from Collision Analysis, rear view.

3D SCANNING BEFORE USING AOGV

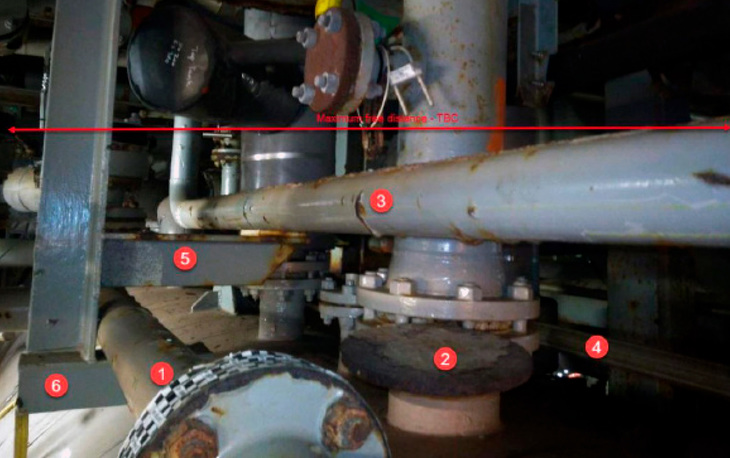

The site visit investigates several intervention points to achieve data for evaluating potential workspace requirements to apply the AOGV tool for positive isolation on the intervention point. Hence, 3D-scannings are modelled and analyzed.

Intervention points include drains, booster pumps, outlet valves and manifold valves. A collision analysis is performed to fit the AOGV tool to the intervention points, reducing on-site challenges once replacing the valves.

The analysis provides requirements for cleared further work to be pursued, investigating access limitations to e.g., torquing of dynamic seals and plug seals, affecting choice of plate and check of availability and the appropriate AOGV tool.

CERTIFIED LIFETIME EXTENSION

The valves are to be replaced while on-line production continues, avoiding costs of a turn-around. This is possible as the AOGV tool mechanically installs a barrier to isolate process segments leaving oil & gas installations with certified lifetime extension.

Intervention Point, Overview