The super critical CO2 (SCCO2) technology does exactly what it is intended to do: removes blockages. Blockages along with other contaminants are removed from systems like i.e. hydraulic control line systems.

Scope of Work

This case unblocks and back-flushes a TRSSSV hydraulic control line on a production platform UKCS, Northsea. Blockages leading to a Cold Well Operation, halted several periods during the previous years as the SSSV fails to gain functionality. Avoiding to pull up the subsea completion, the SCCO2 technology rids the system of not only one blockage, as anticipated, but several blockages in the system.

System Data

- ID of the hydraulic control line: 3.048 mm

- Length of the hydralic control line: +/- 1,700 ft

- Calculated volume: 3.781 ml

- Type of blockage: Unknown

- Assumed location of blockage depth: 1000 ft

- Max. pressure: 17,200 psi / 1,086 bar

- An indication of barium is found in the system

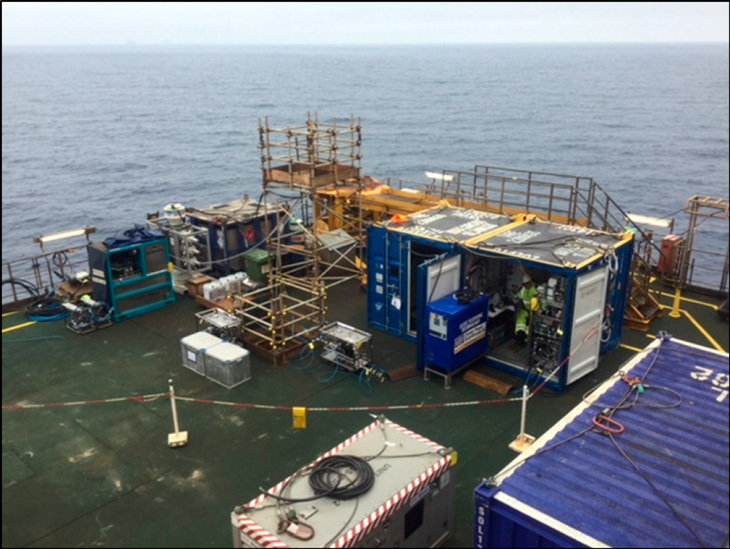

Operation set-up on site

System Set-up

The SCCO2 unit is set-up to 450 bar.

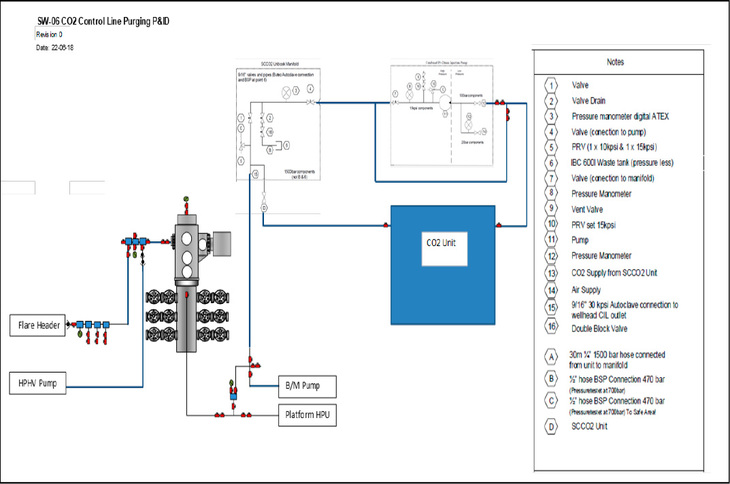

P&ID of the SCCO2 unit and possible tie-in points for additional units

Process

A base point is defined stating intervals of bleeding off and of measuring NAS classes.

The critical point is to empty the line from oil gaining access to the blockages.

To empty the line pressurized CO2 must gravitate through the layer of oil penetrating the blockage below.

Succeeding, the CO2 dissolves the blockage emptying the blockage off liquid whereby the blockage material becomes fragile.

Dissolving the blockage, the pressure is released causing the CO2 to expand a hundred times. The established density of the CO2 and oil mix carries blocakges out.

Results

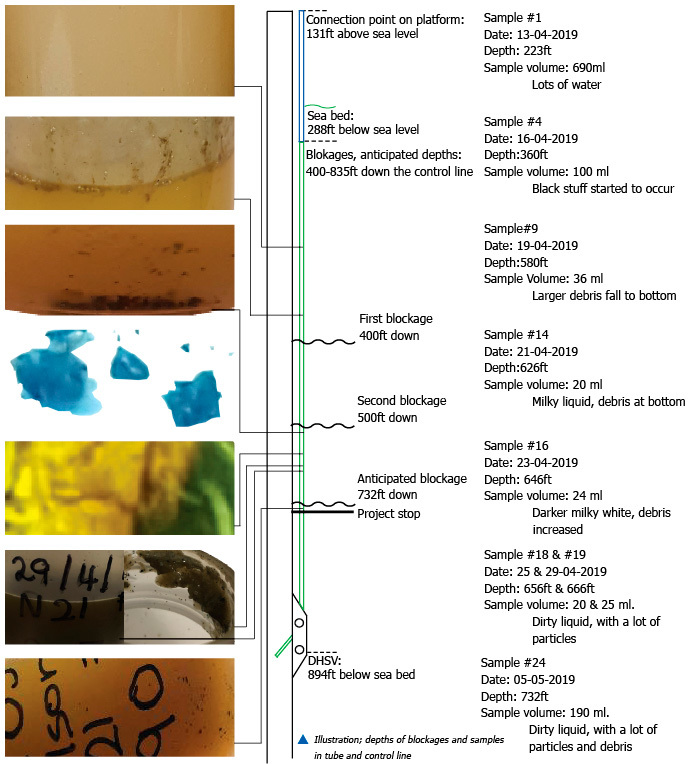

Shocked, the customer finds that the system fault is caused not only by one blockage; but by three different types of blockages clogging up the hydraulic control line.

The SCCO2 back flushing method proves to work out an issue otherwise not solveable without pulling the entire completion.

Improved Bottom Line

“Around 1 in 10 wells shut-in during 2017 in the UKCS. If lost production from shut in wells is 10%, by restoring 10% of these wells, we can raise UKCS production by around 16,000 boe/d – at $ 70 bbl, this is worth $1.1 MM per day.” (Source: The Oil & Gas Technology Centre, used in a customer presentation on OWI2019EU). Of this potential a proved technology using CO2 in its supercritical state, contributes restoring approximate 44%. Extrapolated to $490K value of lost production to be saved per day using the super critical CO2 technology in the UKCS alone.

Excerpt from another case, showing the three blockages in the CL.