A major Danish operator avoided particles in the oil thereby extending life time in the WTG hydraulic and gear systems by using a cleaner oil than delivered: Efficient off-line filtering during transit time benefited the client, using NAS Class 15/13/10.

Lifetime Extension

Risking a top tuned performance to operational malfunctions, IKM Ocean Team proved the usefulness of the SOCOT concept: The oil became offline filtered 15-20 times during transport by a 5 my filter, and again in the nacelle, oil was filtered before added to the system. Offline filtering ensureed efficient use of time and less oil handling. The oil used in the system was ISO class 15/13/10 purified from ISO class 17/16/12 as delivered, ensuring lifetime extension of the system including control valves, pitches, crane, oil cooler, gear etc. Oil can be filtered to an even cleaner standard on demand.

Registration of Oil Sample

Umbilicals Hoisted to the Nacelle

Reduced Oil Efficiency

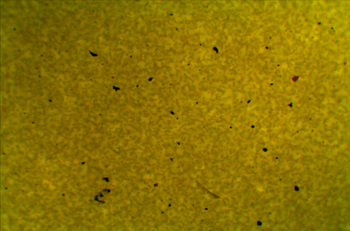

Oil needs to be clean for optimum output processes. Actual samples taken on site showed e.g., an oil delivered at ISO class 17/16/12, one or two classes below desired quality. Oil purity is often reduced due to dirt in the handling process, salts, or sands from the environment, which all reduces the lifetime span of a component or of the lubricated system.

Damages

The metal in contact with the contaminated oil will not only be damaged but create further metal particles to be carried around in the system degrading the hydraulic components as i.e. control valves, the pitch system and crane, as well as a gear box or other lubricated parts.

Efficient Purity Solution

For example, the trim of a control valve will be worn out by erosion of hard particles and hence not close the oil flow when needed, or the life time of a gear can be reduced significantly by contaminated oil.

The Old-Fashioned Way

Not benefiting from a SOCOT concept, the oil must be filtered before poured in to canisters. This is a time costly process and does not ensure the proper cleanliness as the process requires handling and pumping through pump and hoses not included in an offline filtering process. By using cans, barrels, or canisters the oil may be contaminated, unfortunate when filled into the hydraulic tank or gearbox.

Client Savings

The client avoided a direct loss of production as well as costs to change oil and components unplanned and in ‘the old fashioned way’ including cost of vessel, components, technicians, valuable offshore time and lost production by having the wind turbine generator out of work. On the contrary, the client used oil purified within the transfer time, with minimal handling and optimized time efficiency.

Solid Particles from Oil Analysis under Microscope

SOCOT Off-line filtering during transit.

Economy of Scale

The SOCOT concept includes safe and efficient oil handling: IKM Ocean Team obtains economy of scale purifying and converting oil on up to three offshore wind turbine generators a day.