When Wind Turbine Generators (WTGs) have been in production for several years, bearing grease degrades. Such a problem caused inefficiency to our client, a major OEM and energy producer in the USA. Our project took place in the Mid-West.

Proactive Client

When grease in bearings degrades and hardens, it is not efficient as lubricant and bearings become warm. Proactively, as our client were, they acted on the problem replacing the old fat with the new. However, the two grease types were not compatible leaving the problem still to be solved.

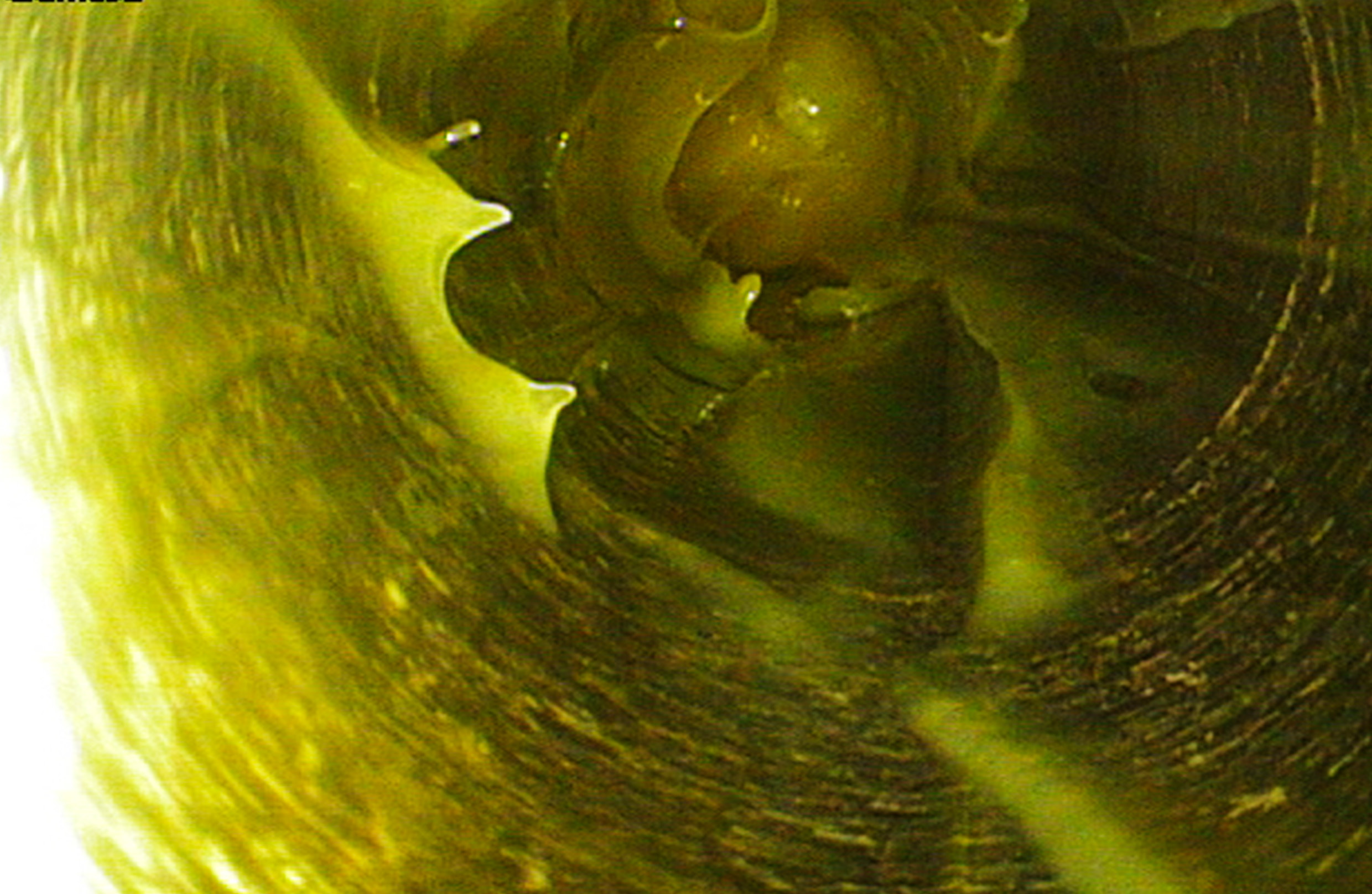

Grease is dissolved.

Technical Knowledge

IKM Ocean Team use our patented technology to rinse out the bearing grease with our customized quipment. Technically, a solvent is added to the grease diluting it easing the flushing procedure of the system.

Risks

Normally, the grease replenish process is associated with a dirty job for technicians manually scratching out old grease leaving grease spots randomly in the nacelle. Also, opening to the grease bearing risks dirt particles to pollute the bearing system.

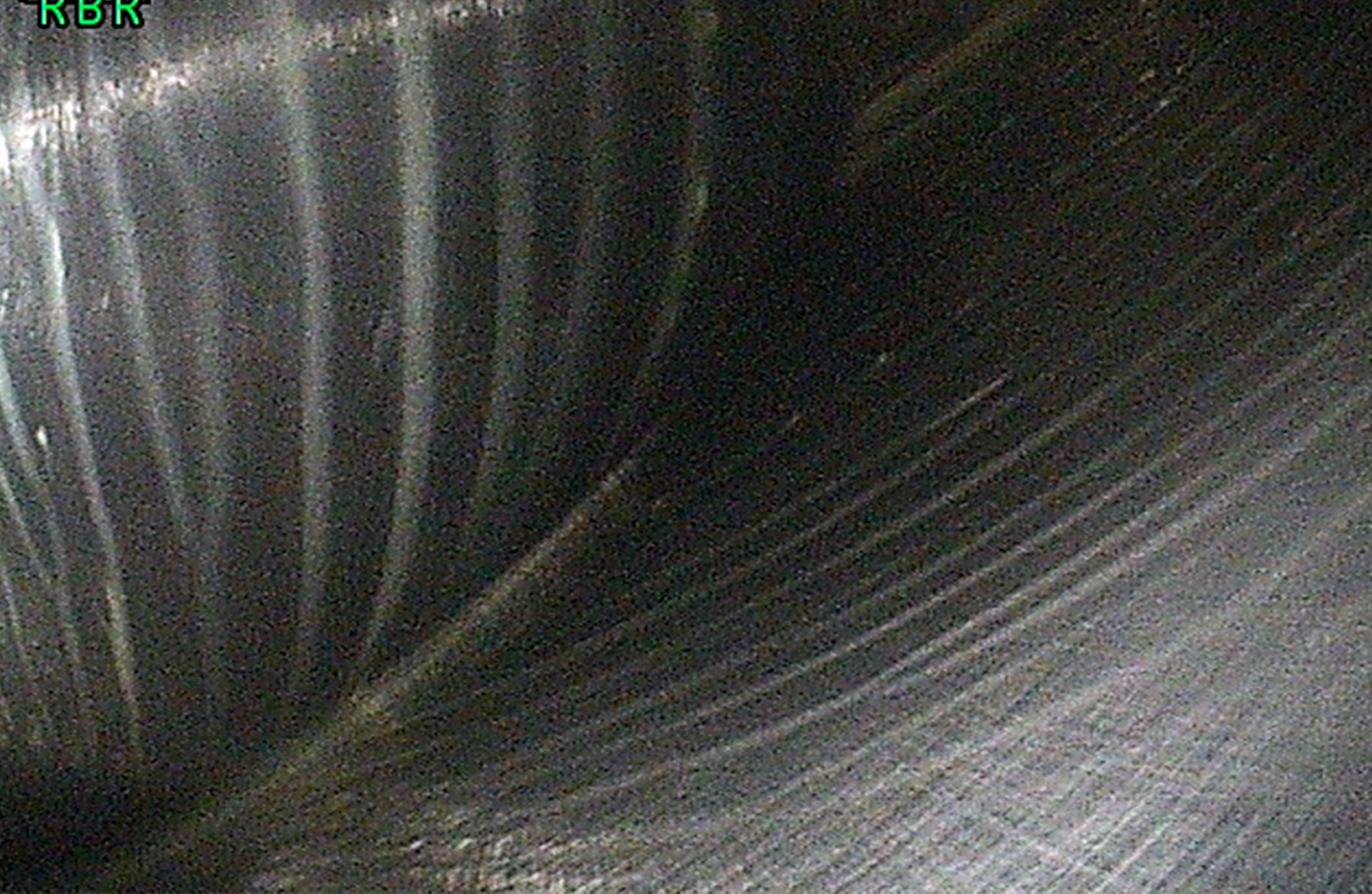

Efficient Work Process

IKM Ocean Team purifies the grease bearing in a closed loop, not risking foreign particles to enter the bearing system: Old grease is directly run into closed containers, not leaving grease spots in the nacelle and technicians’ work processes are improved. The IKM Ocean Team Bearing Grease Replenish technical unit is simply ‘plugged’ on to the bearing system, the grease is diluted, pumped out into closed containers and the system is flushed with oil. This process is build into one unit.

Grease in the process of being pumped out.

Our Client’s Success

Our client is now ready to continue replenishing grease on more WTGs. They obtain a reliable production at its most efficient point, and the technicians’ work environment is improved as

well.

- The Grease Replenish operation takes 1 day/WTG incl. both front & rear main bearing

- Including up-tower flushing / filtering

- Cleanliness down to 4407/NAS