The lightweight solution makes on-site purification easy and cost effective

New Procedures – New Demands

A new market is created in the wind industry as oil additives strive towards a ’fill-for-life’ concept:

Reducing the number of oil changes in the life time of a wind turbine by adding additives to the oil used creates an equal demand to improve the cleaning procedure for the oil cooling circuit in gearboxes cooperating to obtain the common goal: Improve the lifetime of gearboxes avoiding cross-contamination.

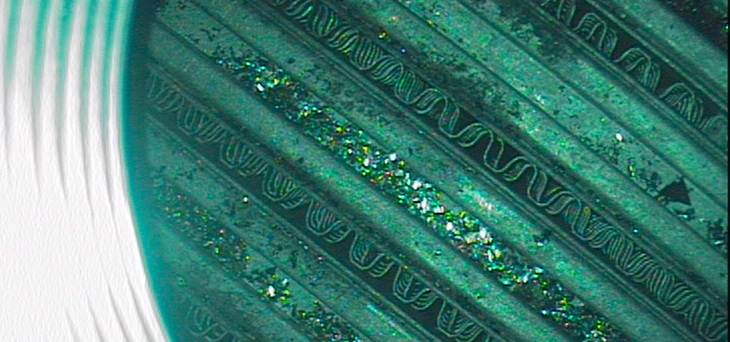

Details of cooler outlet before flushing

Easy Operation in the Nacelle

This inexpensive technology simply implements with the oil change equipment without installation and time costs. Such, a turbulent flow condition RE>3000 interconnecting pipes, hoses, cooler and gearbox is obtained for an efficient operation.

Desired Turbulence

Turbulence created cleans of the inner walls of the cooling circuit and Gear box. Turbulence is obtained by modifying the cooling circuit by a flushing circuit adding air to the oil and raising the pressure in the cooling system until a forceful release of the pressure is allowed.

Details of findings

Enhanced Turbulence

The release of pressure further enhances the effect of the turbulence creating induced sound waves. The accumulator effect is for the purpose momentarily modified to act as a resonance body for the induced sound waves as well as a reservoir for additional compressed air, both adding to the effect of turbulent release of particles from the inner walls of the cooling circuit.

IKM Ocean Team Windcare purifies down to small ISO/NAS classes

Protected Operation

The volume of the filter house dampens peak waves during the forceful release of turbulence, again reducing the forces on the heat exchanger and thereby minimizing potential damage to the heat exchanger.