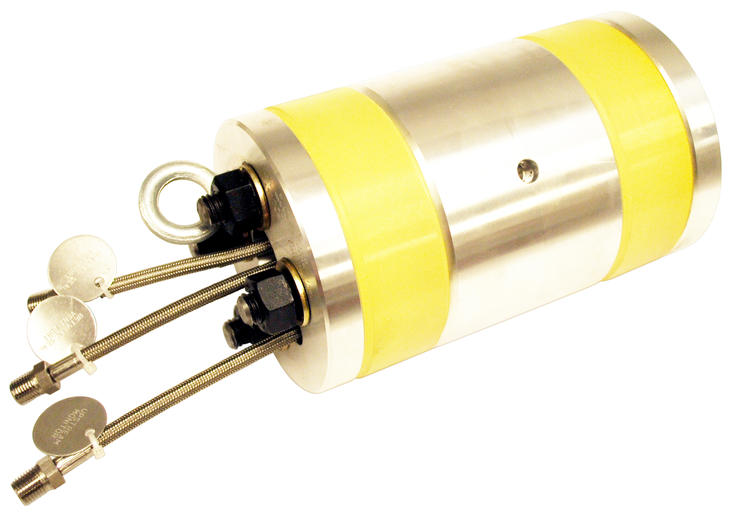

DBB-10P160-02

DOUBLE BLOCK AND BLEED PLUG

Distance Between Seals :102 mm

Installation:

Normal Installation Torque : 271 Nm

Maximum Installation Torque : 373 Nm

Bolt size / Deep Socket Size [in] : 1 5/8"

The Double Block and Bleed (DBB) plug revolutionizes isolation and testing of pipe connections. The DBB plug allows an operator to positively isolate and monitor potentially explosive vapors during “hot work”, then effectively hydrotest the new weld connection with one easy to use tool.

The aluminium/steel construction makes the tool highly portable and easy to position. The volume of water required for a test is so small that testing can be accomplished using a hand pump. This greatly facilitates testing in remote areas of the facility.

Features

• Safely isolate hot work from any residual upstream gases

• Positive pressure barrier created between the seals

• Dual port system can circulate water (or other media) between seals, providing increased cooling capabilities during pre/post weld procedures

• Lightweight aluminum and steel construction - easy to maneuver

• Reduces fill times