Workshop services

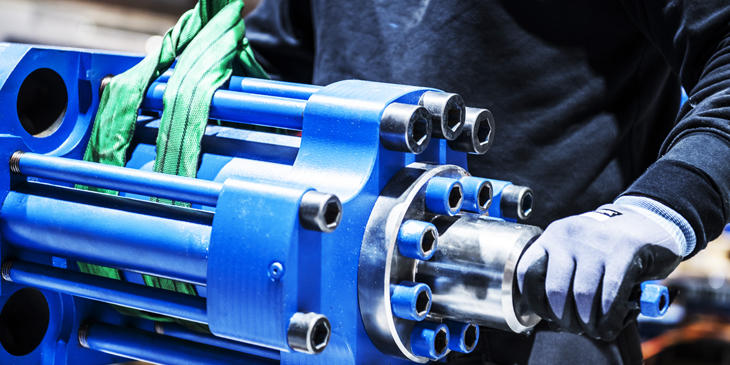

IKM Pressure Control performs service and maintenance on all pressure control equipment for well interventions. This is done via a comprehensive process consisting of disassembly, inspection, assembly and testing. We ensure that all maintained pressure control equipment is in compliance with regulatory and customer requirements.

Since 1999, IKM Pressure Control AS has been a supplier of pressure control equipment for the oil and gas industry in Norway and abroad.

The company provides maintenance services from inspection to finished product according to the current requirements for the equipment in question.

With its long experience, IKM Pressure Control AS has built a solid supplier network that allows the company to maintain all types of valves, HP risers, BOP, lubricators, safety heads and other pressure control equipment that require maintenance, upgrade or classification.

Our technicians have extensive experience and knowledge in pressure control equipment maintenance.

IKM Pressure Control has customised premises with suitable test pits for pressure of up to 20K. All inspection equipment is digital and complies with stringent pressure test reporting requirements.

IKM Pressure Control offers fatigue testing of all types of equipment. With our own 4-point bending test apparatus, we can test the pipes/connectors < OD 10".

IKM Pressure Control AS offers repair, maintenance and testing of pressure control equipment. The workshop has all kinds of connectors for coupling to the customer's connection. We use digital measurements when reporting results. All testing is done in a safe zone with multiple cameras for inspection of leaks or other information.

- Pressure test: 0 – 22.500 psi

- Medium: Water/Hydraulics

- Test area: 12m x 4m

- Crane capacity: 6.3 mT

Digital pressure measurement

- 7 stand-alone cameras

- 1 stationary camera, including panorama, tilt and zoom