Many applications require a robust subsea motor coupled to one or two pumps. We have supplied such motors to a wide range of customers over many years. These motors are extensively field proven and have therefore a Technology Readiness Level of 7 (out of 7) according to API 17N.

The standard motors are oil filled and have four poles. Their power ranges from 2 to 400 kW. Most of these can be supplied for voltages between 400 and 4160 V. We review the cooling performance and requirements of all new designs and integrate special compensating measures when required.

The housing material is typically seawater resistant aluminum but we have also designs with housings in stainless steel, titanium, and super duplex. Typical options include connectors, mechanical seals, and embedded sensors.

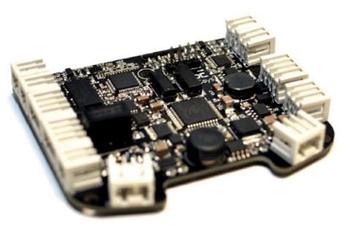

We often integrate a motor monitoring card for predictive maintenance of the motors. The monitoring card reports real-time rotational speed, winding temperature, bearing temperatures, voltage, humidity, and vibration levels over either Ethernet or RS-485.

Our motors can be fitted with advanced sealing technologies and magnetic couplers for permanent installations subsea, according to API 17X and API 17F. We typically do these projects in close collaboration with our customer to combine the motor and the driven load into one package and subsea system.

Standard motor sizes

| Outer diameter of housing | Power | Torque |

|---|---|---|

| 150 mm | 1 - 3 kW | 1 - 20 Nm |

| 165 mm | 2 - 5 kW | 10 - 30 Nm |

| 180 mm | 5 - 10 kW | 25 - 55 Nm |

| 205 mm | 8 - 12 kW | 45 - 70 Nm |

| 240 mm | 12 - 18 kW | 65 - 100 Nm |

| 280 mm | 20 - 50 kW | 110 - 280 Nm |

| 340 mm | 60 - 120 kW | 300 - 680 Nm |

| 385 mm | 110 - 150 kW | 600 - 840 Nm |

| 420 mm | 150 - 300 kW | 840 - 1700 Nm |

| 470 mm | 250 - 400 kW | 1400 - 2250 Nm |

Please contact us for datasheets, CAD-models, and quotations for these motors.