An incorrect storage of completely new nitrogen bottles almost costed the customer a fortune in purchasing of new bottles and daily fines for lost work.

When handling lifting operations from a vessel, it is important to maintain and stabilize the vessel position.

This stabilization happens with a number of automatic regulated thrusters (dynamic positioning) or by emplaced anchors and chains.

When the sea is rough and the waves are high, the movements of the vessel are too powerful for arming the wells or anything similar situated on the ocean floor or on fleets.

Our customer had discovered a completely new wave compensator solution enabling more stability and effectivity during rough conditions on and in the ocean.

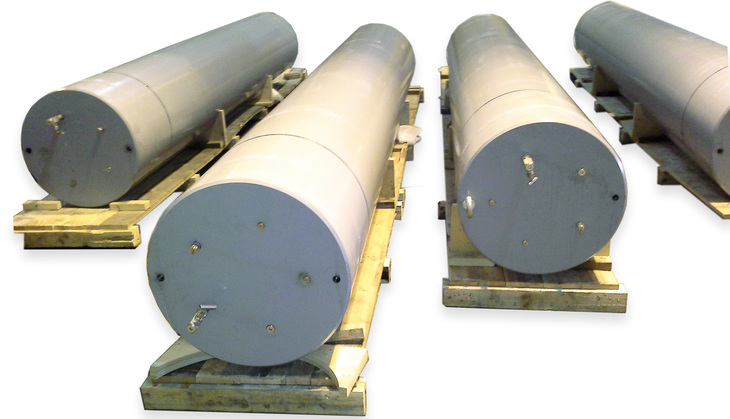

The solution included six newly fabricated 4½-meter high nitrogen accumulators placed on board of the vessel and were thereby able to participate in maintaining the ships position.

Incorrect sealing of the accumulators by using the wrong vents and seals allowed salt water and moisture to penetrate and thereby cause the rust.

However, prior to the process of using the accumulators, they found out, that they had been stored incorrectly, and therefore rust was showing on the inside.

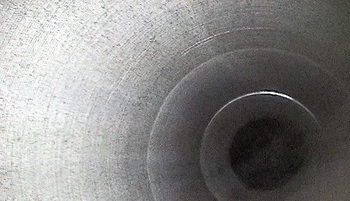

After an in-depth video inspection of inside of the nitrogen accumulators, it was fair to say that they did contain rust deposits. They had to remove the rust before using the bottles, as it potentially could affect the control valves negatively.

Solution Suggestion:

Purchase New Nitrogen Accumulators

Buying new is always a solution to solve a cleaning problem, yet the time of delivery for nitrogen accumulators were six months and time of approval would cross the customer deadline. In addition, the solution would result in expenses for purchasing and expenses in form of possible daily fines.

Our customer chose to search for alternatives and therefore they called IKM Ocean Team.

IKM Ocean Team’s solution: Effective and Timesaving Chemical Cleaning and Passivation

IKM Ocean Team created the right mixture of chemistry to clean the accumulators from rust deposits. Every accumulator was filled with carefully tested chemistry and left to soak for 12 hours.

After the chemical cleaning process had ended, the accumulators went through a new video inspection and approval by the customer. Afterwards, the accumulators were nitrogen dried and passivated. Finally, the customer tightened the reduction vents securely to make sure the former issue would not arise. The entire process lasted only 3 days. The following day, the customer attached the nitrogen accumulators to the vessel.

Nobody exceeded the deadline, no daily fines issued, and the cost and time of buying new nitrogen bottles saved!

Photos above clearly show the badly infected nitrogen bottles.

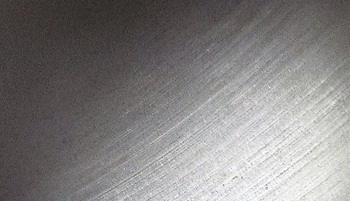

Photos showing the bottles after chemical cleaning ready for passivation.