An oil production platform in Brazil had major problems with their acid boilers.

Several of the 4 boilers had been out of order for almost one year. The production was very unstable and not profitable.

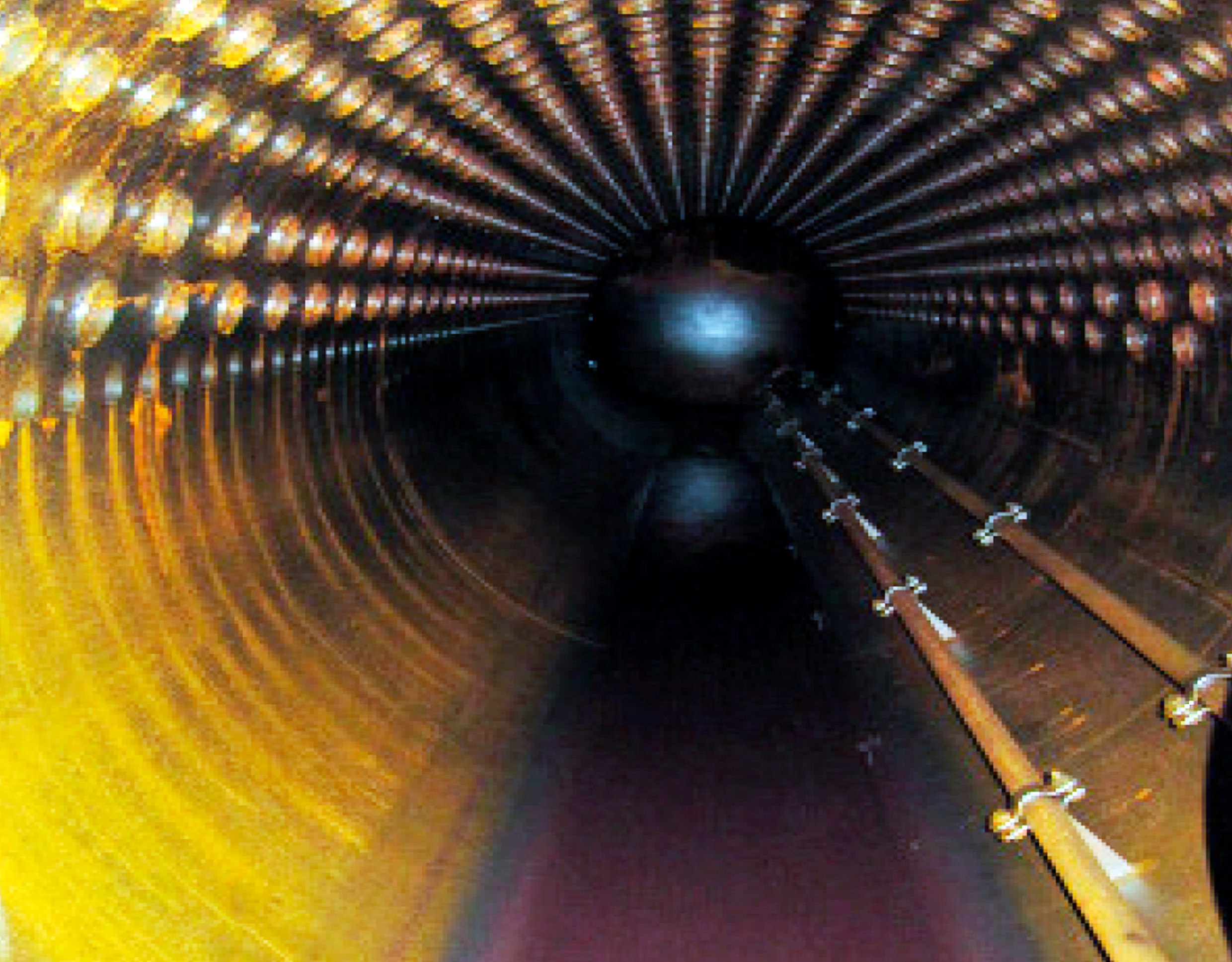

Boiler inside

Solution

IKM Ocean Team was contacted and a serviceteam of two technicians and equipment was sent to take care of the job at the platform in Brazil.

The boilers were inspected both inside and outside. Excessive magnetite was located inside the spools, primarily in the half bottom end of the horizontal spools section.

Flakes of excessive magnetite were unfortunately taken into the system where it would provide major damages in the outer surface.

Also, a significant and unusual amount of corrosion was observed. Most of the corrosion seemed inactive.

Because of overheating, the boiler had seriously cracking which had been tried remedied by welding the cracks together again with limited success. The consumption of diesel for heating the boiler pipes had risen dramatically and thus increased the economic burden.

Boiler inside, before chenical cleaning

Boiler inside, before chenical cleaning

After the chemical cleaning, the steel pipes were clean and without excessive magnetite deposits and crusts. Finally, the boiler was desiccated by use of nitrogen to extend the lifespan of the boiler.

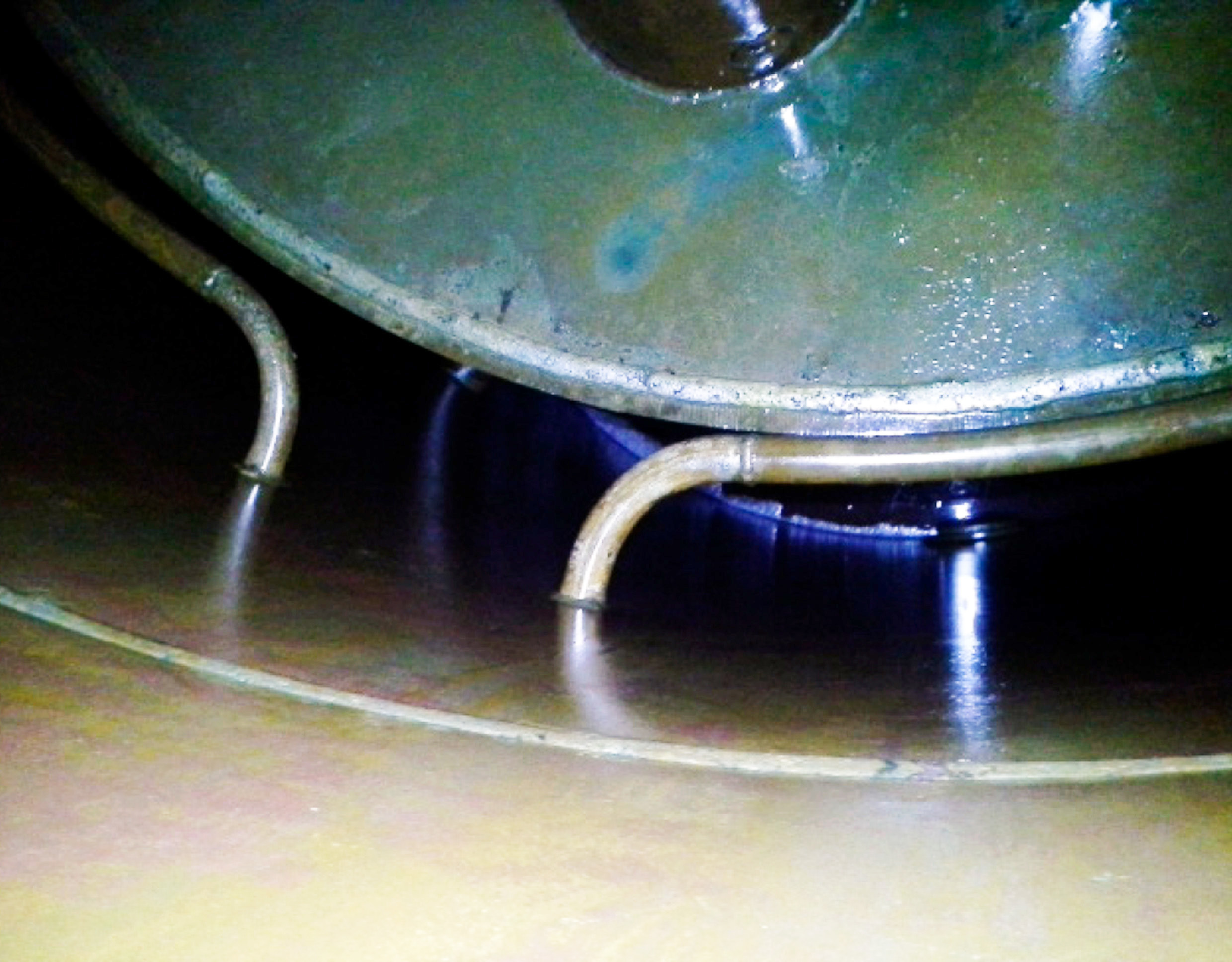

Boiler inside after chemical cleaning

Boiler inside after chemical cleaning

The entire process took less than three days; and the boilers were fully functional again. In addition, the cleaning process also managed to reduce the cooling time of the 50 cubic meter boiler with 33% from 12 to 8 hours.