IKM Ocean Team’s combination of know-how and large scale capacity equipment used on sites ensures clients’ efficient fuel economy.

Industry boilers, boilers on FPSO’s, and on vessels need an efficient fuel economy, reducing consumption. Deposits may cause blockages or leaks. The IKM Ocean Team solution includes extended boiler durability reducing risk of consequential damages, higher cycles using less resources, and less demanding maintenance of boiler water.

The IKM Ocean Team Solution Keeps up Efficiency

Too high loads on the system causes i.e. deposists in the steam and condensate system, visually resulting in foam. Corrosion caused by oxygen is also a known issue prevented by keeping alkaline conditions in the boiler. Boiler scales and deposits treated by i.e., phosphate and polymer treatment decreases thermal resistance on furnace wall, lessening fuel consumption.

Process

Visually inspecting the boiler with cameras kicks off the chemical cleaning process. Additionally, the IKM Ocean Team equipment allow big volumes of liquid to be rinsed on-site.The type of surface contamination determines the chemical circulated in the client’s system. Circulating the chemical might happen under heated conditions using the boiler’s burner or with a parted flow of waste heat.

Turn-key Service

IKM Ocean Team is able to deliver a total package deal including cleaning with the suited chemistry, disposal of used chemistry, as well as a follow up trend analysis, and system monitoring.

Exploded Boiler Tube

The IKM Ocean Team Solution

- includes extended boiler durability reducing risk of consequential damages, higher cycles using less resources, and less maintenance of boiler water.

Consistent Quality

Consistent Quality

Deposits of fouling substances negatively affect the performance of the process systems by reducing flow, increasing pressure drop, impairing heat transfer, or, in the worst case, causing blockages, corrosion, or leaks.

Through many years of experience IKM Ocean Team has built up an unique knowledge of which chemicals to use in particular situations. We are constantly testing new chemicals that are more efficient and environmentally friendly, and we only select the best to be used in our service programs, delivering a consistent quality worldwide.

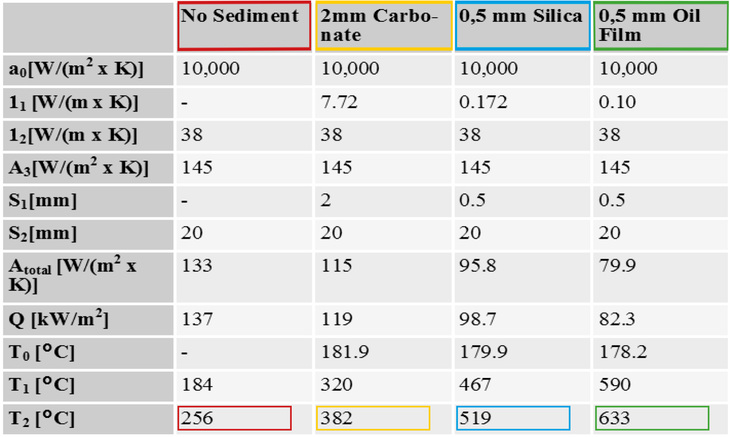

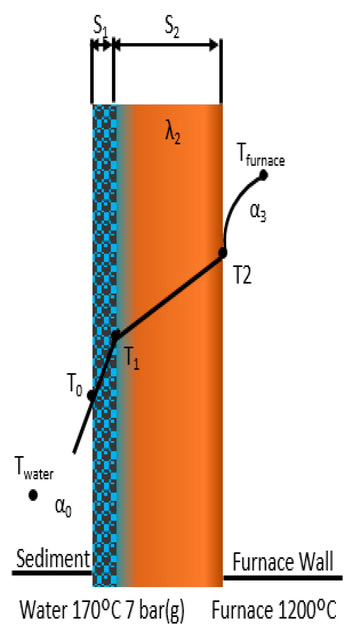

If the water side of a furnace wall is fouled with e.g. carbonate, silica, or film, the temperature of the furnace wall increases due to added thermal resistance.