Optimise your maintenance program with IKM Ocean Team’s Contamination and Fluid Condition Monitoring Program including technical recommendations for optimisations.

Like a blood sample, a small amount of oil can show signs of contamination, degradation, and/or wear and tear.

In machinery the oil sample will carry small particles of metallic debris, which can give indications of any wear patterns, which may be occurring within the system. Using state of the art instruments we can determine the composition and concentration of these metallic particles and indicate which part of the machinery is wearing at abnormal rates.

Information generated from an oil analysis can be used for prediction of a potential problem with the oil or machinery before it becomes critical and long before it becomes evident to the maintenance engineer.

This enables you to plan an efficient and optimal preventive maintenance of your system, saving you for costly downtime and minimise your maintenance and repair costs.

Oil for analysis.

Analysis for all Applications

All mechanical equipment will benefit from a fluid condition monitoring program. Our laboratory is accredited to UKAS ISO17025 and has more than 30 years of experience in analysing samples from all types of lubricated systems including:

- Engines – diesel, petrol and gas powered

- Hydraulic systems

- Gearboxes

- Compressors

- Turbines – gas and steam

- Heat transfer systems

- Circulating oils

- Transmissions

- Transformers

- Cooling Waters

Analytical services:

- Greases

- Fuels

- Coolants

- Ferrography

- Product formulations

Chemical and microscopy examination:

- Sludge/deposits

- Metal debris

- Filters

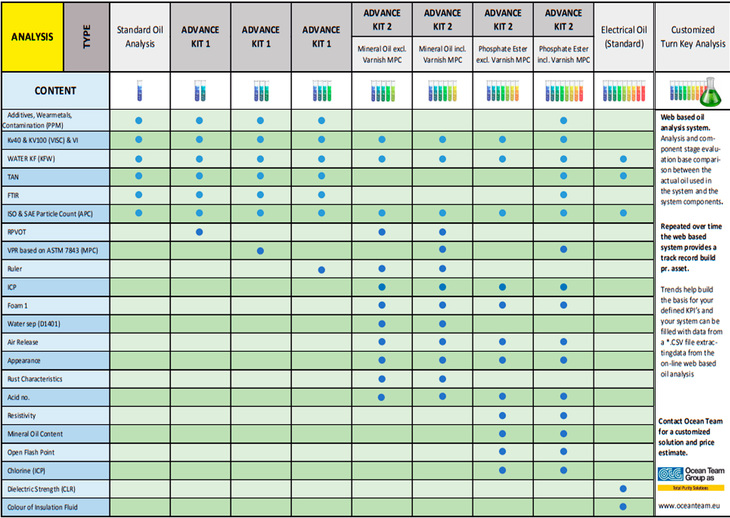

What Analyses do We Offer?

Our testing ranges from basic contamination checks to full-blown system oil condition analysis, whereby we perform lubricant condition checks to ascertain whether your system oil is fit for further use.

Our routine testing program includes among others analysis of wear metals, ISO 4406 particle count, viscosity, and colour.

Beside our routine testing program, we offer a range of additional tests, which is especially recommended to be performed at least twice a year on in-service turbine oils:

- Foaming sequence: ASTM D892

- Demulsification number: IP 19

- Emulsibility: ASTM D1401

- Rust prevention characteristics: IP 135 A&B

- Air release: IP313

- Oxidation stability (RPVOT): ASTM D2272

- Acid number: ASTM D664

- Varnish potential: ultra-centrifuge method and patch colourimetry

- Water content: Karl Fischer method

- Flash point closed cup: ASTM D93

For further information about the different additional tests, take a look at the below Technical Insight Box below.

We have divided our analysis program into three different standard packages.

The content of each of the analysis packages is outlined in the table on the following pages.

TECHINICAL INSIGHT

Explanation of Turbine Oil Analyses Methods

Why are the additional oil analysis tests important to the optimization of your maintenance program? Following a short explanation of the different additional tests within our Turbine Health Check Service Program:

Foaming Sequence: The foaming characteristics of turbine oil can be analysed at the laboratory by blowing air through the oil and measuring the amount of foam generated. Too much foam can strongly affect a lubricant's ability to perform and can be derived from contamination of the oil, excessive agitation, or cavitation.

Emulsibility: In steam turbine applications it is inevitable that the lubricating oil will come into contact with water; therefore it is vital that the oil’s ability to shed water is monitored. Oil that sheds water quickly will continue to perform in a desired way. Oil that continues to hold in the water will lose lubrication and oxidation resistance capabilities.

Rust Prevention: All turbine oils will contain additives that will help inhibit rust. Rust particles can cause abnormal increases in wear metals within the lubricated system and increase the rate of oxidation.

Air Release: The air release properties of oils need to be monitored to ensure that the in-service oil continues to have the ability to detrain entrained air. Too much air in lubricating oils can lead to increased oxidation of the oil and reduced film strength properties.

Oxidation Stability: Over time turbine oils will oxidize. Monitoring the amount of oxidation resistance is critical to ascertain the remaining useful life of the oil. Using the RPVOT test enables the laboratory to make a comparison against an unused RPVOT level to determine the oils’ condition.

Acid Number: Abnormal increases in an oil’s acid levels may indicate severe oxidation or over-heating of the oil. These acids can corrode metallic components.

Varnish Potential: Varnish found within lubricated systems can affect operating temperatures, clearances and increase component wear, it is usually derived from oxidised oil by-products or additives. It can be analysed by colourimetric testing or the Ultra-Centrifuge test.

Ultra-Centrifuge Test: This test measures the amount of insoluble material and oxidised material present within the sample.

The test gives results of 1 through to 8, with the higher number showing higher levels of insoluble material present. This insoluble material can indicate possible varnish potential problems and oils with a result higher than 4 should be monitored closely.

Water Content: The amount of water present in turbine oil will reflect the potential for rust formation and reduction in oxidation resistance. Therefore, it is vital that these water concentra-tions are monitored and kept at low levels. Water can also cause sludge formation and affect the oil’s viscosity.

Analysis packages outlined in the figure above.

Online Trending and Web Site Access

The test results are sent as a *.pdf file attachment to specified e-mail addresses. Further, we offer client specific passwords enabling customers to access their complete historical database of all sample results and reports from a single secure website. Results are uploaded daily and the first page check allows you to view the status of recently uploaded results.

Results can be split by location for users who sample from multiple sites, and sample reports can be searched by many parameters including equipment make, model serial number, or oil grade.

As well as viewing all samples submitted online, other aspects of our oil analysis services can be accessed, including:

- Online trending

- Creation of individual unit or multiple plant sampling schedule

- Ordering sample kits

- Email the laboratory

- Print sample bottle labels

Does your Oil Analysis tell the Truth?

The reliability of an oil analysis is dependent on how the oil sample is extracted from the system and how it is treated afterwards. To secure reliable test results IKM Ocean Team offers our assistance with representative oil sample extractions in accordance with ISO 4021, ISO 4407, ISO 3722, NAS 1638 and AS 4059.

Misleading results from oil analyses can result in inefficient and/or insufficient maintenance of your systems. A reliable contamination monitoring program secures the most optimal maintenance of your systems. Carefully following the oil sample procedure is imperative.

Carefully following the oil sample procedure is imperative.