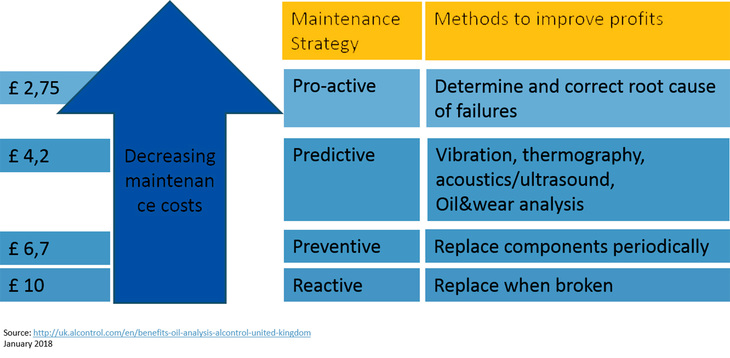

With increasing costs and tighter deadlines, the need for proactive maintenance strategies is greater than ever before. Optimize your proactive maintenance strategy by completing our root cause analysis; an essential tool in maximizing your assets life.

Similar to blood samples, just a small amount of oil can show signs of contamination, degradation, and/or wear and tear. In machinery, the oil sample will carry small particles of metallic debris, which can give indications of any wear patterns, which may be occurring within the system. By using state of the art instruments, we determine the composition and concentration of these metallic particles and indicate which part of the machinery is wearing at abnormal rates.

Introducing the Ruler, a view into the health of lubricants. The Ruler meassures antioxidants in the oil and uses the data collected to provide information to create a trend on the oil. The actionable information provided is an important tool when creating a pro-active maintenance strategy.

Root Cause Analysis

Information generated from an oil analysis is used for prediction of potential problems with the oil or machinery, before it becomes critical and even long before it becomes evident to the maintenance engineer. This is the substance to the root cause analysis, which can save companies loads of money. The root cause analysis enables you to plan an efficient and optimal preventive maintenance of your system, saving you costly downtime and minimizing your maintenance and repair costs. Our laboratory has more than 30 years of experience in analyzing samples from all types of lubricated systems determining the root causes of the issue.

Benefits from proactive maintenance

- Less or minimized downtime

- Minimizing maintenance

- Decrease on repair costs

- No unplanned breakdowns

- Equipment runs more efficiently, which reduces energy consumption.

- Maximization of assets life

- Budgeting is in higher control and overall cost reduced, cause of above meantioned reasons.

From Root Cause Analysis to Proactive Maintenance

When oil is not performing as expected or failing prematurely an examination is needed. By understanding the root causes of varnish build-up and oil degradation, we are able to understand the impact on the rotating equipment. To identify the cause of failure a root cause analysis is provided, and a strategy of problem-solving is developed. Having full understanding of what has happened, is happening and, more important, make sure it does not happen again, is a key component in reducing risk and increasing reliability.