An elder vacuum-toilet system required constant maintenance from two men approximately 10-12 hours a week. It was important to take action to avoid a full system breakdown.

The system pipelines were long and with a countless number of tortuous bends. In order to remove blockages the client would cut the pipes in areas they assumed blocked. Then after trying to clean on the inside, the client re-gathered them the best possible way. A difficult and perishable solution. More and more cut rings appeared and thereby, also a greater risk of further blockages. Not only were the hours of maintenance manifold, also the toilets failed continously; a major irritatation for everybody on site.

Besides blockages, the pipes suffered from corrosion damages. It was important to act fast. If pipes started to leak, extremely bad hygiene could risk infection among the platform crew. The customer approached IKM Ocean Team to investigate on better solutions.

IKM Ocean Team’s Solution: Installation of a New System

As IKM Ocean Team penetrated the pipes with a video inspection camera, it revealed a very thick inner coating. Samples were picked out in order to find its origin. By a closer sample review it indicated a huge amount of layered uric acid stones. It was difficult to conclude on other infecting particles, so samples were tested with chemistry, yet, no chemistry was able to dissolve the stone. Due to this and because of the badly shaped pipes, the client decided to skip both the chemical- and mechanical cleaning. IKM Ocean Team suggested to remove and deposit the wast toilet system and a following installation of a new pipe system. This time using pipes with a greater diameter.

Samples were send for analysis with chemistry testing. No chemistry was able to break down the stones.

Uric acid stones and other growth lie layer upon layer, almost similar to growth rings of a tree. The passage keeps decreasing.

The alternative was to continue using the old expensive system including the cost of two men working the long hours per week. Hours, more constructively usable within oil and gas objection. While still using the previous system, the customer constantly, ran two vacuum pumps in order to maintain the vacuum pressure inside the system.

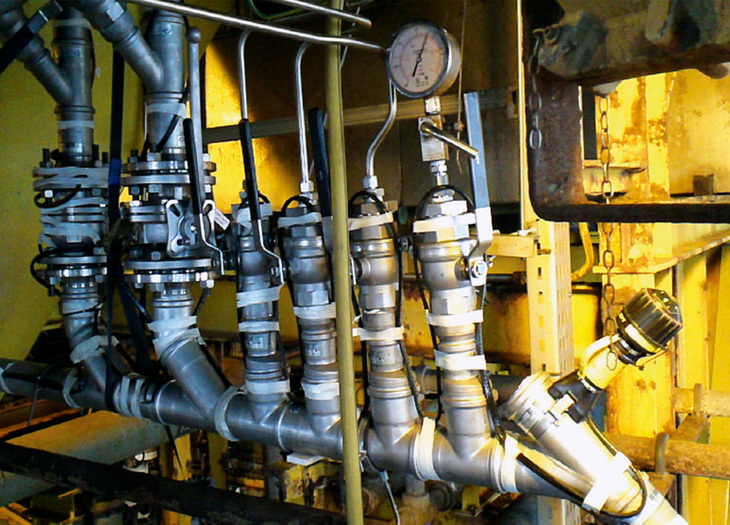

IKM Ocean Team spend only two months on changing the system to a new with a wider diameter. This change reduced the suction pressure significantly as well as it reduced the wear on the toilet bowl. Now, the customer only needed one vacuum pump switched on periodically. IKM Ocean Team rebuild the toilet system while the old system was still up and running.

The customer were very satisfied with IKM Ocean Team's efforts and left a fine opinion on their behalf. The customer especially mentioned IKM Ocean Teams’ professional planning of night- and dayshifts.

The newly installed pipe system. In order to avoid frost skips, the pipes wrer dressed in heating cables.