Demand of the SCCO2 technology leads to manufacturing of the second generation.

As a client tells us: ‘Alternatively, a complete workover would cost around € 33.500 K’.

Second Generation Improvements

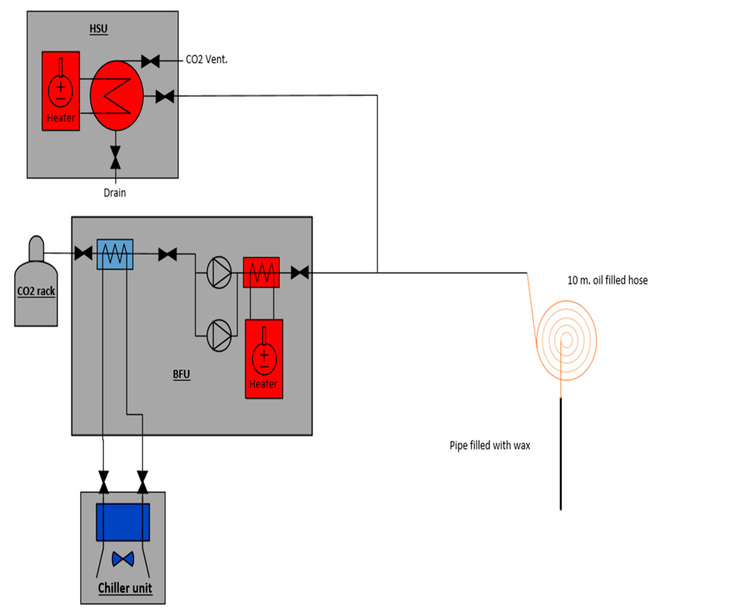

The second generation SCCO2 technology is manufactured to suit ATEX Zone 1 and 2 requirements. So, logistics are easier off-shore positioning the units. The manufactured technology is available in sets of three units to ease the application of required Scope of Work in individual cases:

- Back-flush Unit

- Heating Separator Unit

- Chiller Unit

- All connected in a manifold

Back-flush and Heating Separator units respectively

Resilient Material FAT’ed

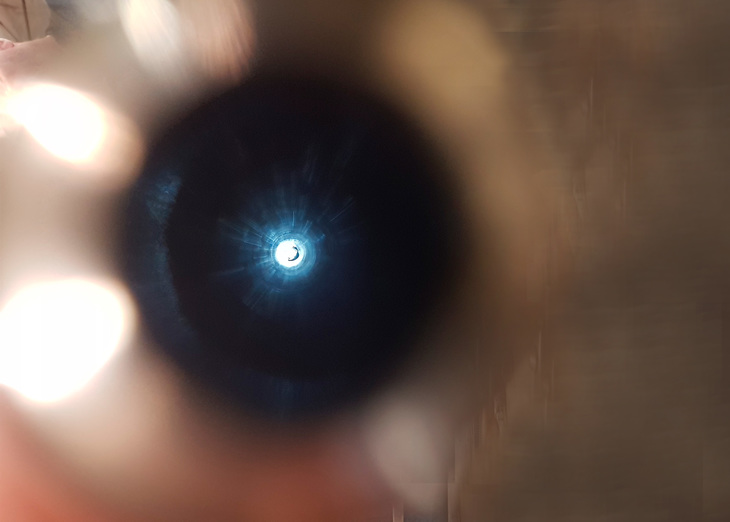

A FAT is completed (Factory Acceptance Test). As a part of the FAT, a blockage removal case is simulated to test the new generation of units up against a “close to real life” -situation. Clogging the entire length of the pipe, thick wax residue collected from a launch pig is added to simulate a resilient blockage in a one-way line i.e., a control line.

Test pipe fully loaded with clogging wax

Challenging the System

To challenge the functionality of the newly build units, the blocked pipe was during test installed in the end of the test line, to make sure that the clearing of the blockage was as challenging as possible in the given conditions. In this report the highlights from the test will be shown through various pictures taken during testing.

Test system set-up

Test Specifications

A series of Back-Flushing cycles was performed, resulting in a successful clearing of the line.

Pressure: 500 bar

Temp.: 100° C

Duration: ̴ 2-3 hrs.

Re-number: ̴ 20,000 – 200,000

Dehydrated wax affected by the SCCO2 Back-flush cycles.

Wax prior to SCCO2 back-flush cycles.

Samples of hydraulic oil and debris from blockage. Extracted liquid from within the blockage including debris

Results

Completely clean on the pipe inside is ridded from all wax extracted backwards out through the narrow Inner Diameter and the Separator unit. This unique method of using CO2 in a super critical state to backflush a blocked one-way system has proven to be efficient. Even in cases that could otherwise be almost unsolvable without having to do a complete workover of the system.

The SCCO2 Back-flush cycles cleaned the narrow ID pipe

Re-gaining Lost Production

A previous case exemplifies a partly cold well that daily could produce equivalent to approximately € 2,7 mio per day - if it was not halted by a blocked injection line. Diminished revenues due to production obstructions and abandoned wells are not necessary when applying the SCCO2 to the market.