Flushing newly manufactured pipes for off-shore operation avoiding particles otherwise stuck on the inside of the pipe wall to be flushed out of the coil using turbulent flushing.

4 x ¼” OD x 0,049” wall, L: 2400 Ft, Nickel based Alloy 825

Costly Consequences

The applied technique and procedure avoid malfunction of systems and the need for shutting down assets sensitive to production due to blockages caused by contaminated systems.

Normal Procedure

Conventional NAS 6 flushing is a well-known method to clean inside newly manufactured long and narrow pipe systems (‘pigging’).

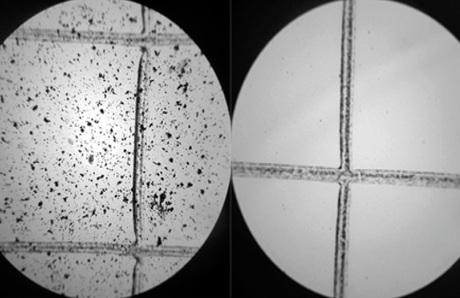

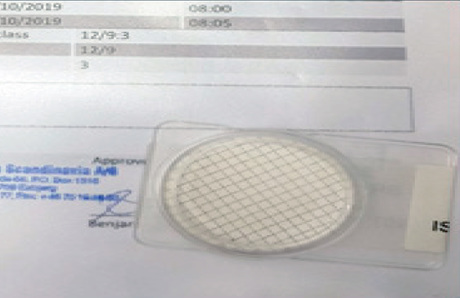

NAS class 12, 4 km CIL

Same 4 km CIL after SCCO2 flush.

NAS 12 to NAS 5 in 1 hr 40 min.

SCCO2-clean is Cleaner

It is proven that lines that have already been flushed with the normal ‘pigging’ method, and accepted as clean and ready for installation, were in fact far from clean. The previous photos shows samples taken from a 4 km CIL that was initially accepted as NAS class 6 after being flushed with the normal “pigging” method. The SCCo2 technology proved that the line was far from clean. The line turned out to be NAS class 12+. Keep in mind that this line was marked as ready for installation.

System Set-up

Turbulent flushing flow is mandatory for an effective cleaning. The challenge is to keep a turbulent flow all the way through the pipes. In most cases, this will require a pressure drop of more than 30,000 PSI. This kind of pressure drop exceeds the maximum test operational pressure, which most pipe systems are designed to withstand.

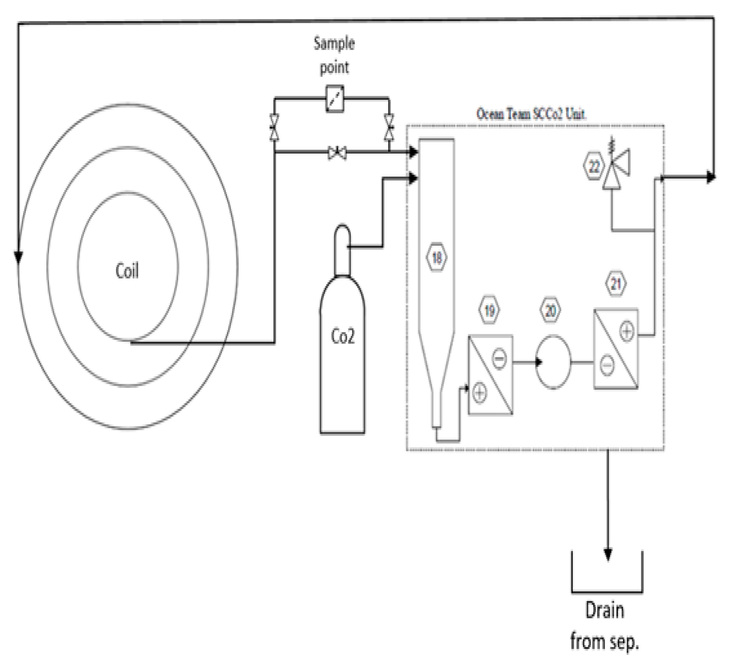

The SCCO2 coil flushing set-up

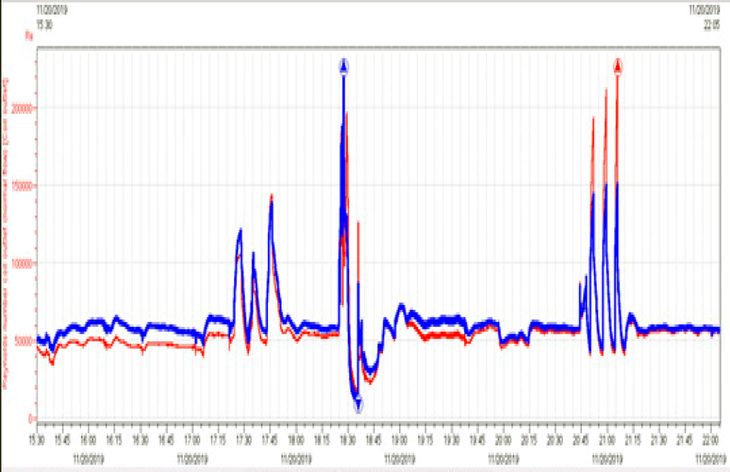

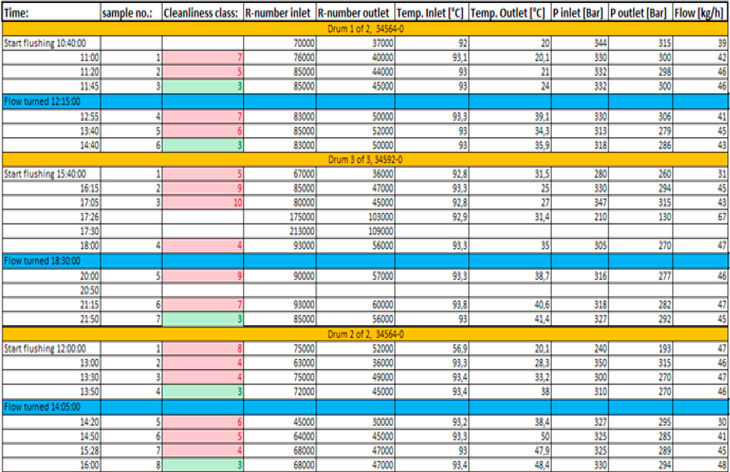

Drum 3 of 3, Reynold numbers

Process

Co2 is processed through the system and pumped through the coil. After the Co2 exits the coil, it enters the unit again through a separator that purifies the Co2 before being reused in the closed loop system.

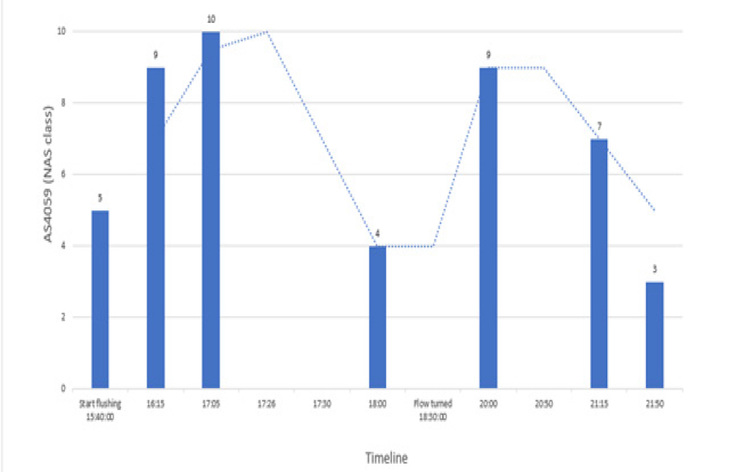

Condition of the four lines were received both before, during and after flushing with SCCO2. Below graphs displays the progress of cleanliness throughout

Cleanliness over time

Results

A much higher cleanliness standard of pipes to be installed in completions prolonging system life time of vital equipment.

- Initial AS4059 class: 10

- Final AS4059 class: 3

- Total time 1 drum: 6 hrs. 10 min.

- Total flush time 4 coils: 19 hrs. 35 min.

Flushing result sheet (excerpt)

Proof of Dirt

The below-showed substance is often seen when flushing coils with SCCO2 and is the result of dehydrated wax that is extracted from the lines during flushing. This type of contamination is almost impossible to remove with anything but SCCO2.

Powder from separator

Reference test certificate