A major Norwegian oil producer wanted an on-line oil flushing. Now convinced, they can save several days per plant while keeping production running.

A Game Changer

Though proven performance since 1996 worldwide, the Online Pulse Flushing patented process is still new to many. For example to a major Norwegian oil producer. Co-operating with ServTech, Norway, IKM Ocean Team performed the ESV maintenance on one of the incoming gas processing plants on the North Sea coast of Norway.

Safety

The gas processing system had become ineffective. As expected, contaminating particles showed up in the system due to common wear. Ineffectiveness in ESD valves must be avoided keeping the process plant safe from a worst case scenario.

A Convincing Case

Flushing the old fashioned way, the full gas process system had to be shut down – and stay unproductive. In this case the oil producer planned the maintenance phase to 10 days of draining, purging and filling.

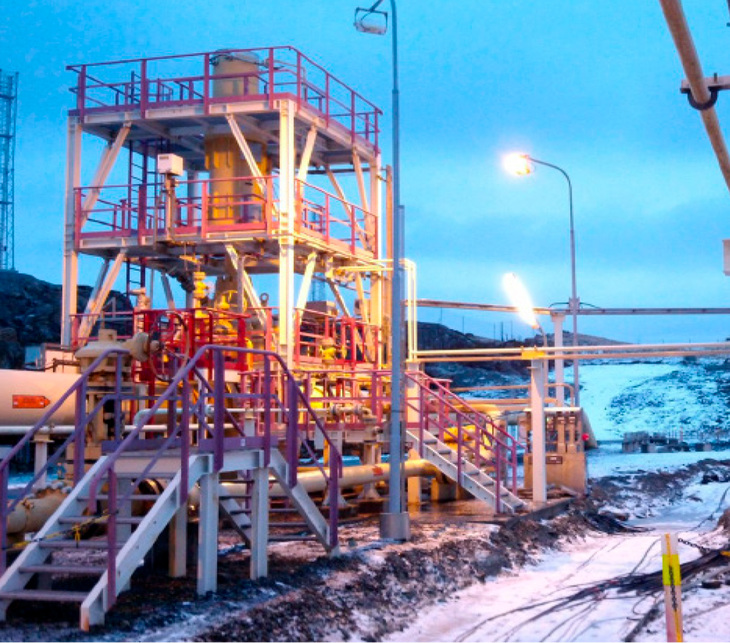

Tower with ESVs on site

Aerial of the gas incoming point in Norway

Using IKM Ocean Team's Online Pulse Flushing no shutdown is needed: The hydraulics of the ESVs can be cleaned while the gas processes under normal operation conditions. Performed in a closed loop no environmental impact occur from oil spills.

This was also the case when convincing the major Norwegian oil supplier to flush online: starting out cautiously, IKM Ocean Team's online-flushing equipment was connected to the 325 bar system

and flushed the hydraulic oil to a NAS class 4 in two days less than planned.

Close-up of the gas incoming point

Your Benefits

No production loss, no oil spill, operational experience from the North Sea and customer benefits as life extension on plants, has proven the success of IKM Ocean Team's on-line pulse flushing.