Oil producing companies now have an alternative to abandon wells gaining access to previous shelved oil resources, safely.

Reactivating Oil Production

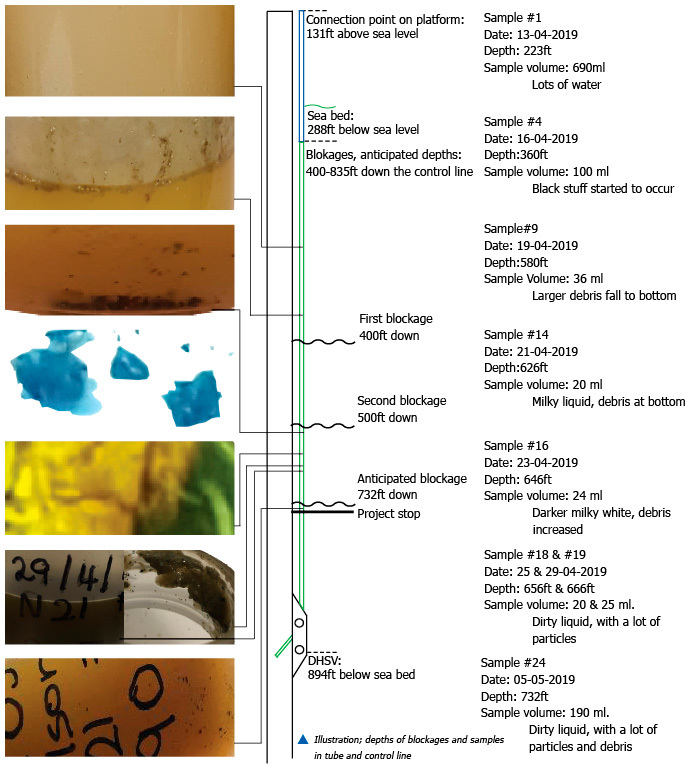

A major oil & gas producer in the North Sea recognizes the need for re-activating a former oil producing well. The well is blocked. It is cold. Estimated blockage depth is 400 ft. (122 m) down the control line. Anticipated, the dirt consists of organic and inorganic material and sludge.

Scope of work included back flushing of an open loop system with a partially blocked control line, to: ‘Carry out an offline SCCO2 treatment to clear the control line blockage’.

- TRSV depth: 894ft (app. 300 meters)

- TRSV depth temp: 60-90°C

- Total CL volume: 3700mls

- Control Line ID: 3.86 mm

- Blockage depth: 400 ft +/- 100 ft- (app.122 meters)

Back Flushing of Control Line

Emptying the control line, low viscosity liquified CO2 is pressurized and injected. Penetrating the control line hydraulic fluid, the pressure is released from the system whereby a rapid decompression empties the line when CO2 expands x100, a so-called back-flushing. Similarly, the blockage is back-flushed when CO2 pools up beneath the blockage and decompresses.

Turbulent flow ensures also the material wall of the control line and SSSV to be rid of deposits. Using a high Reynolds number, particle layer stays under 0.001 mm.

Backflushing is a method to lift media or deposits out of one-way lines. This makes it possible to change fluids or take samples.

Succes Criteria Obtained

Several blockages were found working our way down the depth of the control line; also, at 500ft (152 meter) and 835ft (255 meter) blockages of different types were found. They were

treated in accordance with their type and documented by samples. Reading the pressure loss in the control line and the following pressure raise in the tubing indicates that a passage

through the blockages were cleared.

IKM Ocean Team rid the control line off blockages down to 835ft, with up to 1.18 SG (Specific Gravity). The operator’s operational priorities caused rigging down before clearing the full length of the CL.

Industry conclusion

This case took place in the U.K. where 1 in 10 wells are shut-in during 2017. The Oil & Gas Technology Centre assumes:

“If lost production from shut-in wells is 10%, by restoring 10%

of these wells, we can raise UKCS production by around 16,000 boe/d – at $70bbl, this is worth $1.1 MM* per day”

OWI 2019 EU, Apr 16-18 (ED:* 1MM = 1 million)

Surveys show that top five causes of well shut-ins include well integrity and scale; and that the top eight reasons for amounts lost on production refer to well integrity, DHSV and subsea control failure. These are the cases where SCCO2 opens for the production, and hence, money flow of the producer.

Back flushing liquid expands x100 when depressurized

Source: ‘The Supercritical Revolution’; Thomsen & Amundsen

Illustration; depths of blockages and samples in tube and control line