Super Critical CO2 technology is now recognised as “SHELL TRSSSV Control Line Cleanliness Best Practice - NAS3 Fluid Cleanliness using SCCO2 Technology”

Colin Black, Managing Director, Carjon-NRG Ltd

Traditional Laminar Flow Flushing can Contribute to Well Integrity Issues

Blockages, or partial blockages, encountered throughout the well’s life cycle in Safety Valve Control Lines, Chemical Injection Lines and Subsea Umbilical’s face the following contributing factors:

- Manufacturing wax-like substances

- NAS class 12 particles

Conventionally, pre-completion & prior to installation, lines are polished and filled with the appropriate NAS 6 cleanliness fluid. However, traditionally these lines are not flushed with Turbulent Flow (i.e. a Reynold’s number greater than 3000).

Shell and their suppliers; IKM Ocean Team’s clients, identified that the polishing flid is indeed often NAS class 6, but since only laminar flow is achieved during traditional flushing the lines internals still hold particles to a NAS class 12 size and often contain manufacturing wax like substances.

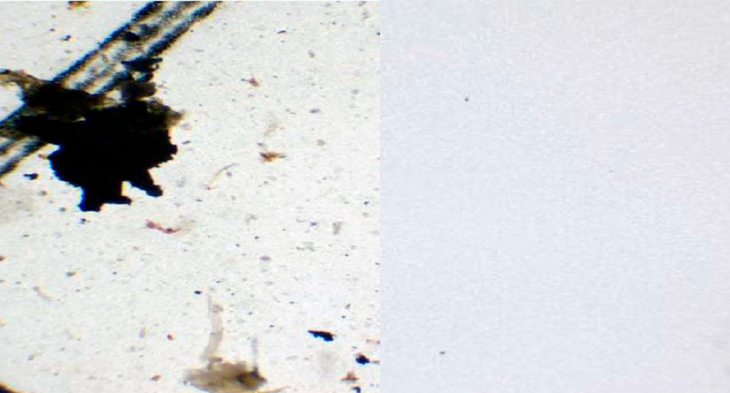

Milky sludge and wax-like blockage material.

Consequently, these NAS class 12 particles and waxy substances can contribute to life cycle line blockage issues and associated hydrocarbon production losses and well integrity issues.

Moreover, during a recent flushing project, clients were shocked by the impurities within brand-new lines, never used before and delivered pre-flushed with SV3 to NAS class 6.

Turbulent Flow Cleans the entire System to NAS 3

The Super Critical CO2 Flushing system (SCCO2) is perfect for completion of control line conduits and umbilical’s, because of the low pressure drop over long distances, which can exceed 20 km. with a small inner diameter, lower than 1/4”.

Clients are shocked by the impurities of brand new lines, never used before and delivered pre-flushed with SV3 to NAS 6 ( NAS 3 is showed to the right).

Using this system, a cleanliness of AS4059 Class 3 (NAS 3)/ISO 4407 12/9 can be achieved during pre-installation flushing.

The SCCO2 Flushing Service is Available from IKM Ocean Team and their UK SCCO2 Flushing Partners

Oil, Gas & Energy companies request a NAS class 3 flushed, certified, and sealed control line ready for NAS 6/NAS 3 fluid filling.

A system with this cleanliness, significantly reduces well integrity risk potential as long as fluid cleanliness is also maintained throughout the well’s life cycle. IKM Ocean Team can also flush, filter and analyse Topside Control Panels and systems if fluid cleanliness are compromised.

Request Turbulent Flow

This case study highlights that Oil, Gas & Energy companies who aim to safeguard production may proactively clean control line conduits with turbulent flow using SCCO2 to create turbulent flushing exceeding a Reynolds number of 3000.

Awards

For further details on ICOTA award winning IKM Ocean Team Supercritical Cabon Dioxide Flushing (SCCO2) Technology, please register on:

https://uk.energytechnologyplatform.com/product_service/supercritical-carbon-dioxide-flushing

References

You can also view pro’s/con’s, specifications, Relative Business Impact, TRL, Track record and read reviews from:

- Keith Houghton, CWIE, Shell

- Tom Brighton, Director, Ormesby Consultancy (former Shell, CWI WE (front end) manager)

- Colin Black, Managing Director, Carjon-NRG

- Dave Bruce, Service Co-ordinator – Completion Tools, Shell Supplier.