Conventional oil flushing using turbulent flow is the most reliable method for cleaning of hydraulic systems, including hydraulic top-drive systems. IKM Ocean Team has refined this technology by adding induced waves and thereby making the process faster and more effective.

Hydraulic systems are very diverse, both in size and complexity. However, thanks to many years of experience, IKM Ocean Team has designed and developed a wide programme of flushing technologies, methods and units capable of meeting the ever-increasing requirements on cleanliness in the energy sector world wide.

Turbulent Conventional Oil Flushing

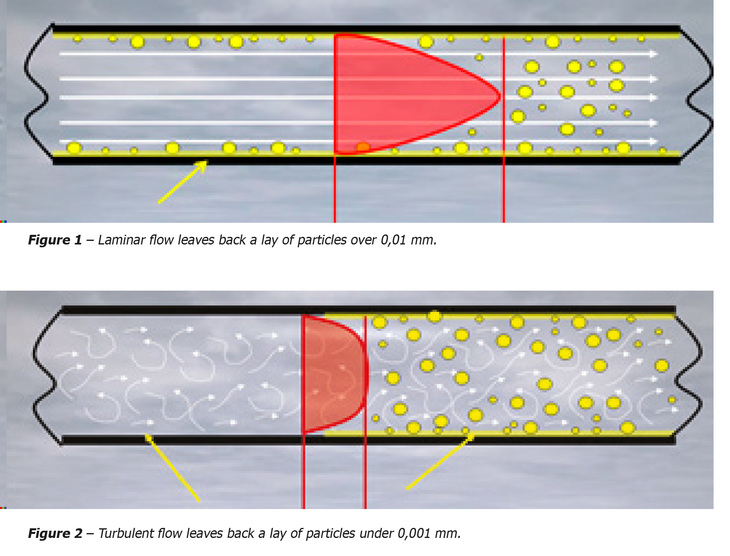

IKM Ocean Team has developed methods for conventional oil flushing using turbulent flow rather than commonly used ‘laminar’ flow.

Flushing with turbulent flow efficiently dislodges impurities deposited on the inside of the pipe system. In comparison, flushing using simple laminar flow will clean the oil, but not the pipe system and it will only be a matter of time, before the oil becomes contaminated again.

Induced Waves

IKM Ocean Team differentiates by adding induced waves to the process of turbulent conventional oil flushing. We expose the flushing oil to pulses, caused by sudden and controlled compressions, in order to create sound waves (induced waves) and an even higher Reynold number in the pipe system. The higher the Reynold number, the more effective turbulent flow you get.

The Result is a Faster and more Effective Removal of Impurities from the inside of Pipe Systems.

The success of the flushing process is depending on many different parameters. IKM Ocean Team always plans and tailors the solutions to the individual job to ensure the best possible results with the least trouble for the customer. We focus on being quick, efficient, reliable and safe.

References

As a job reference, IKM Ocean Team has performed oil flushing of hydraulic spools in the top drive system at Noble Byron Welliver. Facts about this job are listed below.

FACTS

Place: Noble Byron

Job description: Flushing of 1½” pipes between power unit and monkeyboard.

Degree of purity: NAS class 5

Used filtration: 3 my

Equipment: OTS.200.200.7.ACMU.SS316

Enclosed are pictures from the job and datasheet on the used equipment. We have similar equipment approved for operation in Zone 2 gas areas.

Datasheet on the explosion-proof version is also available. For further references IKM Ocean Team has performed flushing of hydraulic systems for several well-known companies, including Maersk Drilling, Maersk Oil, Hess and Dong Energy.