A major oil producer on the UKCS tried several times to open their well. Using the SCCO2 technology for the same purpose loosened 3.5 liters of contaminants extracted from the Chemical Injection Line (CIL).

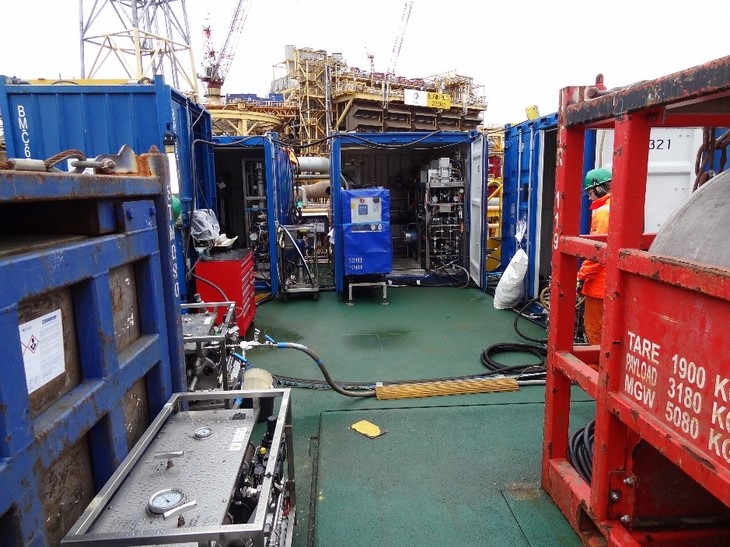

Equipment set-up, off-shore on site

Financial Importance of this Well

If this line is operated efficiently the production contributes with a significant revenue from the well as it produces approximately 18K BOEPD.

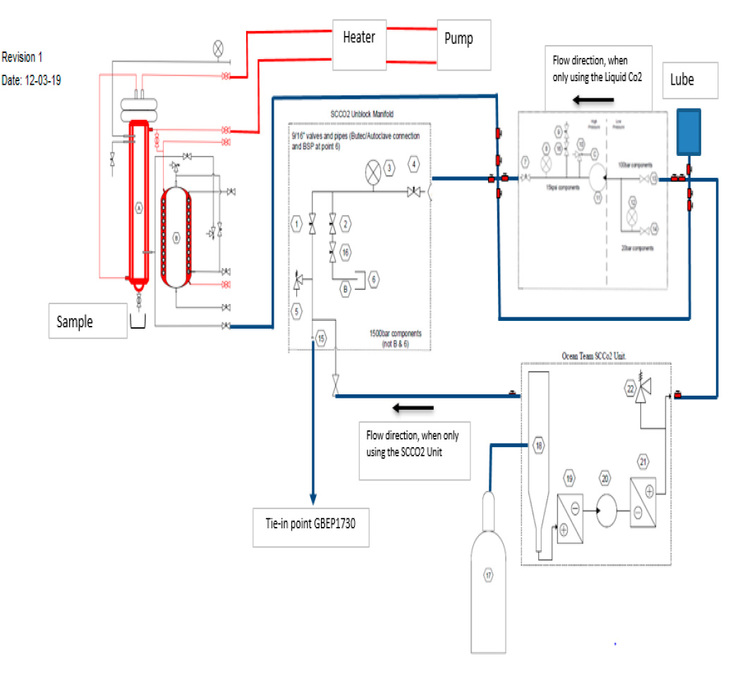

System set-up

3 Attempts - and then SCCO2

Lack of scale inhibitor caused the first shut-in. The operator flowed the well for short periods.

Adding scale treat but not following in-house procedure to circulate DEG (Diethylene glycol or methanol) blocked the line again.

Third operator-led attempt opens the well by pumping down methanol causing a blockage at the injection mandrel.

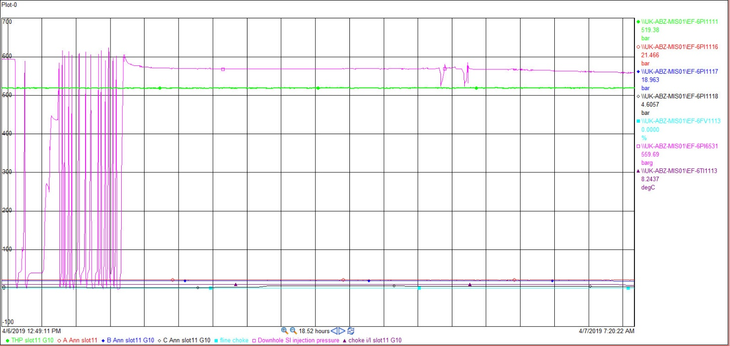

Screen-shot from well monitoring system; Purple is CO2 pressure

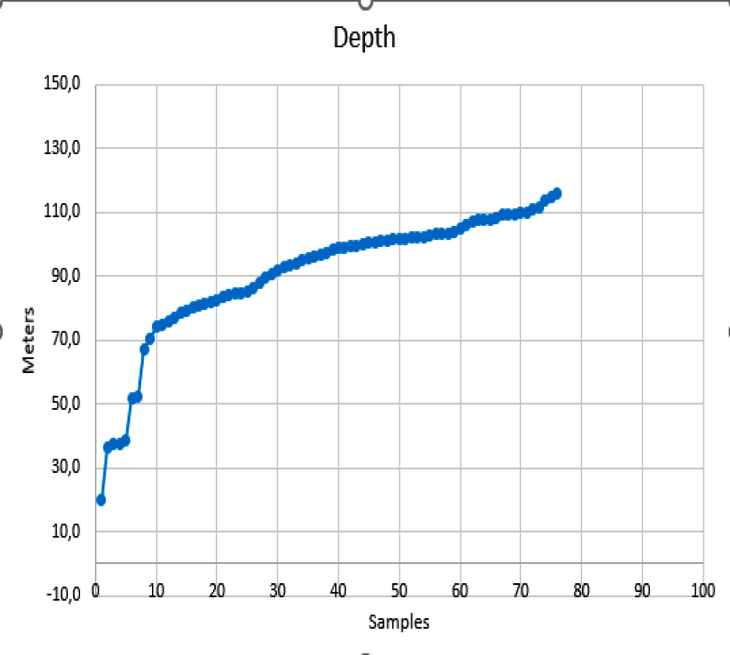

Depth reached during operation

Well data

- Gas Condensate producer well

- Depth and length of injection line: 1802.41 mtr. to injector mandrel.

- ID: 6.2 mm: Capillary tubing

- Density: Scaletreat = 1.17 g/cm3 (20 degrees C)

- Temperature at mandrel = 140 degrees C

- Control line pressure = 520 bar

Process

A diagnostic pre-test narrows the time estimation down as the operating process is established. To obtain the best fit for this particular system, customized procedures are made, inclusive the filling and emptying process.

Safety factors and risk assessment are performed including systems and seals as the well is needed hot for this operation.

Amounts and contaminated fluid samples

The control line was pressurized up to 630 bar and then bled off to 520 bar repeatedly; various amounts of ml. fluids returned, indicating the position and severity of the blockage.

Results:

3.5 liters of mixed liquid and various sort of contaminants was extracted from the Chemical Injection Line (CIL). The customer chose to follow-up analysing the samples for revealing system faults generating an FTIR report.

![]()

First extraction of CIL

![]()

Sample with contaminants

New Generation SCCO2

The new generation SCCO2 unit is certified to operate in Zone 1 and 2. One set consists of a pump unit, a heating seperator unit and a chiller unit for efficient application of each one of the three applications the SCCO2 technology is used for.