Modern lubricants are sophisticated products. In the luckiest case, mixing incompatible lubricants leads to degradation of lubricant performance in an undamaged system. At the other end of the spectrum deposits, sludge, and tacky residue may form to increase wear and plug filters. Lubricants reactions will depend on the products in the mixture, the end-use application, the relative concentrations of products, and the total volume involved.

Spectroscopy

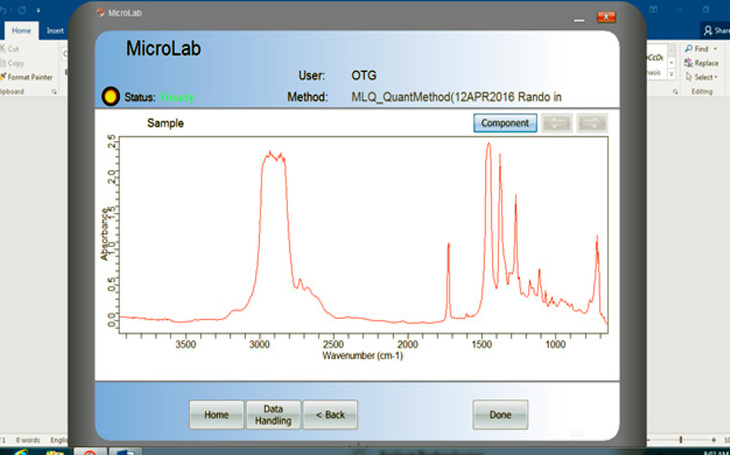

Fourier Transform Infrared Spectroscopy (FTIR) verify the composition and quality of materials. For example, the method can confirm the identity and quantity of incoming raw materials reading wavelength for each substance measured, also for non-routine samples.

Work Process at Client’s Site

Converting old oil to biodegradable oil, for example, the percentage of old oil must not legally exceed 2-5%. The FTIR analysis traces named substances. Defining client based reference samples, IKM Ocean Team can obtain knowledge for further operational decisions on-site within 30 seconds whether converting oil on an oil & gas platform, on a power plant, or at a wind turbine.

An on-site a laptop is hooked up to the FTIR device. Placing a drop of oil under the reader, the FTIR analysis starts off measuring wavelengths of the substances.

Oil analysis with a 1% deviation from total purity

Benefits of FTIR

FTIR analysis supports a beneficial choice of additives obtaining performance and avoiding lost production due to lubricant ineffectiveness.

Traditional methods to provide knowledge for operational decisions included sending oil samples for testing at a chosen laboratory. This process would take 10-12 days, which would make it ineffective and un-operational.

Using FTIR on-site IKM Ocean Team instantly knows when customer oils have reached performance properties: avoiding contamination to spread unwanted particles from one location to the full system and decreasing further costs of wasted oil. On-site analysis optimizes the time and amount of oil used for flushing.

Mobile FTIR unit

Further Benefits

Allowing a broad spectrum of investigation and comparison IKM Ocean Team can define a customer’s special need for analysis in defined cases.