In order to secure system reliability and minimize risks of break-down, it is crucial to secure a high level of cleanliness in any system. The purpose of this text is to give some practical instruments to how you can implement “Total Purity” into your hydraulic- and lube oil systems.

The absolute most important step for implementation of efficient “Total Purity” activities is that all employees share the same attitude to purity. This attitude must be obtained through a clear goal in respect to purity, which is decided and backed-up by the management and spread all over the company.

How Clean Should the Systems Be?

The suppliers of components and systems specify a recommended degree of cleanliness required for their products. However, the technical data sheets issued by the manufacturers will often mention a recommended maximum degree of contamination rather than a recommended operational degree of contamination.

This means that if you operate your systems with a degree of contamination, which correspond to the one stated at the technical data sheet from the manufacturer, you are actually moving on the edge of a possible breakdown.

As a rule of thumb, systems should be operated with a degree of contamination, which lies 1-2 classes under the recommended maximum degree of contamination for the most sensitive component of the system.

Did You Know…

…the size of the most harmful contaminants for most hydraulic- and lube oil systems are far smaller than what can be seen with the naked eye? meaning that we are facing an invisible enemy!

The limit of the human eye is 40 my, corresponding to half the thickness of a human hair. The size of the harmful particles are 4-14 my.

Break down of entire systems are costly and may be avoided at a lesser cost.

What Are Contaminants and how Are they Added to Your Systems?

In brief, contaminants cover anything that is not meant to be there. We distinguish between the following types of contaminants:

- Solids - metals, dirt etc.

- Fluids - water, incompatible oils etc.

- Bacteria

- Fungus

- Air - stressed fluid.

Contaminants can be added to the systems in many different ways. Generally, the sources of contamination can be divided into three main groups:

- Remains from installation

- fluid sealing materials, welding spatters, grease from manufacturing etc.

- System generated contamination

- caused by wear and/or breakdown of system components, poor system filters etc.

- Added from the outside surroundings

- in connection with fluid transfer, repairs, connection of other systems etc.

Every time you open a closed hydraulic- or lube oil system you risk to add contaminants to the system. Therefore, it is recommended to flush new systems before it is put into operation as well as in connection with repairs and installation of new components in old systems.

What Is Oil Flushing?

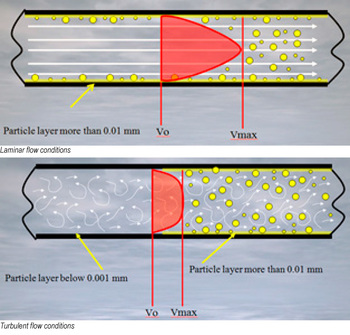

Generally, most hydraulic- and lube oil systems are designed with “laminar” flow conditions. This means constant operation without cavitations or vibrations.

The problem with laminar flow is that with time impurities will deposit on the inside of your system and will not be carried out and caught by the inline system filters.

In order to obtain an efficient cleaning of your system, it is therefore necessary to use flushing with turbulent flow, which will dislodge and remove the impurities on the inside of the system.

Oil flushing is more than just starting up the internal system pump and circulating the oil through the system filters; a so-called “polishing”. Polishing will clean the oil but not the pipe system, whereas flushing using turbulent flow both cleans the oil and the system.

TECHNICAL INSIGHT PART I

Known Misinterpretations about Oil Flushing

The understanding of the importance of flushing has become more widespread, but some misinterpretations still exist:

- “Stepped Filtration”

A commonly used theory in some companies is the definition of flushing requirements on the basis of “stepped filtration”; starting with a 50 my filter, followed by a 25 my filter, a 10 my filter and at last a 3 my filter. This method is totally waste of time and money, as the size of particles to be sorted out is 5-15 my. By using the above method the possibility to catch particles of size 5-15 is very limited during the first three stages.

- The Flush-time

In some cases companies have asked for a “12 hour flushing” or about the duration of a flushing operation. The reply to this question is that there are a large variety of factors, which affect the flush-time. It is almost impossible to say in advance, how much time it will take to obtain the desired degree of contamination in a system. In case of such inquiries we offer a rough indication based on our previous experience.

The three most important Categories in Flushing Are:

- Flushing filters

- Flow velocity

- Viscosity/temperatures

Flushing Filters

The heart of any flush unit is the filter. If you use poor filters the flushing will become a long and costly affair.

The permanent filters of a system cannot always be used for cleaning of the oil in connection with flushing. Instead we use special flushing filters in connection with our transportable flush units. The purpose of these special filters is to increase the filter capacity during flushing.

The filtration characteristics of the flushing filters are chosen on the basis of the degree of contamination required by the supplier of the individual system.

Flow Velocity

The most efficient flushing is obtained if the flow velocity is relatively high and/or the viscosity relatively low. In such a situation a turbulent flow will be created in the pipe system during flushing.

Turbulent flows are obtained, when Reynolds figures are as follows:

RE = w x d x 1,000 > 3,000

V

w = average flow velocity (m/sec.)

d = inner pipe diameter (mm)

v = kinematic viscosity in cSt

• If RE < 2,000 the flow will remain laminar.

• If RE is between 2,000 and 3,000 the flow will be “disturbed” turbulent.

• If RE > 3,000 the flow will always be turbulent.

Cleaning can be effected in many ways. One method is to expose the flushing oil to pulsations caused by sudden and controlled compressions in order to create an even higher Reynolds figure in the pipe system.

This violent turbulent flow has the effect that impurities sitting on the inside of the pipe system are torn loose and flushed with the oil to the filters of the flushing unit.

Viscosity/Temperatures

The viscosity of the flushing oil is of the utmost importance for determination of the necessary flow velocity. Especially in case of flushing without sufficient possibilities to heat the oil (for instance in strong frost or at high wind speeds) the kinematic viscosity of the flushing oil should be relatively low, and the specific gravity relatively high.

On the other hand, the viscosity should not be too low either, for instance water with viscosity of about 1 cSt, as impurities being torn loose might then just fall to the bottom of the pipe, as the gravity of the liquid cannot carry these particles out from the pipe system in the flow. Consequently, it is necessary to calculate the viscosity to make sure that the particles are carried out to the filters.

Please note, however, that the viscosity should preferably be above 15 cSt in consideration of the lifetime of the components of the flushing unit.

The figures illuminating respectively laminar and turbulent flow conditions.

Heating of the flush oil will promote the removal of dirt from the mounting, which can be fixed in either fat or tectyl etc. on the inside of the pipe walls. Furthermore, the viscosity is reduced, which facilitates the formation of a turbulent flow.

The temperature of the flush oil should preferably be kept above 50°C and below 60°C in order to avoid oxidation of the oil. If the flush oil is going to be discarded after use, or if flush oil with a high viscosity index is used, the temperature might be increased, however not above 80°C.

Quick heating of the flush oil can be done by means of the overflow valve (safety valve), and by maintaining the correct flow velocity during the flushing operation it is normally possible to maintain the temperature of the flush oil. In case of low surrounding temperatures or especially in case of high wind speeds (offshore) it might be necessary to cover the pipes with a tarpaulin or to supplement the heating with a heating element.

“No hydraulic- or lube oil system has ever broken down because of the oil being too clean.”

Cost-Saving Method for Flushing during Operation

IKM Ocean Team has developed a patented method for oil flushing, which enables us to clean during operation without interrupting the production.

The solution is especially attractive for cleaning of static hydraulic- and lube oil systems, large as well as small, and has for instance been used within emergency shutdown systems (ESD).

When is Oil Flushing Required?

It is a balance and a decision to be taken in each individual case as to how much care and how much work, you want to invest in flushing.

It depends on the importance of the reliability and stability of your systems. For instance the hydraulic pilot control for activating a subsea valve for raw oil or gas is a simple hydraulic system, but because it must necessarily work each and every time in the first attempt, extraordinary care is paid to secure minimal contamination. On the contrary, in case of a hydraulic- or lube oil system, which is only started up on certain occasions in a company, and where the components are not of vital importance, only elementary precautions are taken.

It depends on the importance of the reliability and stability of your systems. For instance the hydraulic pilot control for activating a subsea valve for raw oil or gas is a simple hydraulic system, but because it must necessarily work each and every time in the first attempt, extraordinary care is paid to secure minimal contamination. On the contrary, in case of a hydraulic- or lube oil system, which is only started up on certain occasions in a company, and where the components are not of vital importance, only elementary precautions are taken.

Only one thing is sure: No hydraulic- or lube oil system has ever broken down because of the oil being too clean.

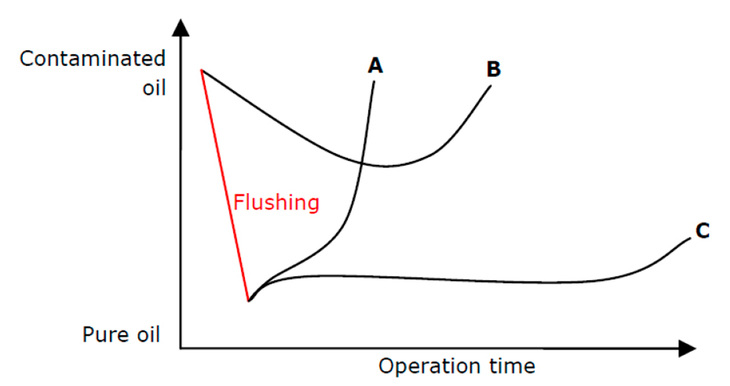

The True Degree of Contamination

The true degree of contamination in a system is not only reflected by the time of flushing, but also by how much the degree of contamination rises, when the flushing filter is disconnected from the circuit. The level at which the contamination stabilizes is called the true level of contamination for the system.

The True Level of Contamination and its dependencies

A = Good flushing, no/poor system filter

B = No flushing, no/poor system filter

C = Good flushing with good system filter

The above figure shows that although the system has been flushed down to a certain level of contamination, the true level of contamination will generally be stabilized one to two classes higher, when put back into operation.

The explanation is that no matter how careful you are, you cannot totally avoid atmospheric particles to be admitted into the system during dismantling of the flushing equipment and connection of the original components. Moreover, the connected components will generate particles in the beginning before the level of contamination is stabilized at the true level.

Regularly Maintenance with Use of IKM Ocean Team’s Oil-Care Program

It is very important, already from starting up a hydraulic- or lube oil system, to carry out a control of “total purity” as part of the maintenance procedure.

Regularly control of the contamination level with use of oil samples can be of great help in identifying and diagnosing system wear. Particles of certain metals might often lead to the identification of certain components under decomposition or perhaps the original source of the contamination. Hereby it becomes possible to optimize the maintenance processes and prevent disastrous system failures.

Part of the oil sample is filtered through an analysis membrane and is analysed by means of an optical microscope in order to decide the type of contamination (by an 'on-the-spot' check). All contaminated particles, which are classified and measured in 4, 6 and 14 my, are evaluated and categorized as either blank metal, brass, black metal, silicon, elastomer and plastic, fibres or others. The numbers and sizes of the particles are evaluated visually and identified in accordance with ISO 4406 class and/or NAS 1638 class.

The final result is an extensive document, which enables you to decide any future interference in case of problems.

Additional analyses can be made at certain intervals to make sure that the measures taken have been efficient, and to get a continuous survey of the systems, which can warn you of an approaching failure in the machinery. Alternatively, this service can give you additional safety in respect to the system you are operating.

By means of a mobile analysis unit, IKM Ocean Team is able to evaluate the contamination level of the oil on the spot and to identify the type of contaminating particles. In this way you get an invaluable remedy to survey and control contamination.

TECHNICAL INSIGHT PART II

How to Take-Out a Representative Oil Sample?

It is of decisive importance for the result of the oil analysis and the particle counting that the oil sample has been taken out correctly.

- Take out the oil sample from a plant with operation temperature.

- Take the oil sample from a place in the hydraulic and lube oil system, where the oil flow is turbulent to obtain a “dynamic sampling”, for instance near a knee-bend or a T-piece in the pipe system.

- Dry capilar hose carefully with a lint free cloth.

- Activate ball tap/measurement clutch to full flow.

- At least 200 ml of oil should flow out before the oil sample is taken.

- Take out the desired quantity of oil without adjusting the ball tap/measurement clutch. The size of the sample should be at least 50% and max. 80% of the volume of the cleaned sample bottle.

- Tilt the bottle at an angle of 25-30 degrees when taking out the sample to prevent contamination from outside to get into the bottle through particles in the air. By tilting the bottle the opening is reduced.

- While the oil is still flowing out, take away the sample bottle when a sufficient quantity has been collected.

- Immediately close the sample bottle, and place the bottle in a bag with a mechanical lock.

If the above is not possible the sample is taken from the tank/reservoir of the system about 1/3 from the bottom “static sampling”.

Precautions when Filling new Oil to the System

- use offline filter units from IKM Ocean Team

When new oil is filled onto the system, the contamination level for such oil will usually be above 19/17/13 in according to ISO 4406 classes, which for most systems will be 1-2 classes too high. This goes for oil either delivered in bulk tanks, drums, or cans directly from the oil supplier. This does not mean that the oil companies are loading dirty oil from their plants, but that transport, handling, and packing processes add atmospheric and foreign particles to the oil, which increase the contamination level about 1-2 classes. This problem goes for oil deliveries from any oil company.

In order to maintain a low contamination level of your system, it is recommended to make use of an external filter unit in connection with for instance filling of new oil or oil from oil reservoirs.

Through an independent extra fine filtering (offline filter unit) the purity and quality of the oil and the system will be improved more than through the regular system filter (inline filter). Especially, fine particles will be absorbed, and in this way early wear and tear of the system components is avoided, and finally the life of the oil is prolonged.

Further advantages when using an offline filter unit are:

- Possibility to replace elements without stopping the system.

- Large capacity of the filter elements.

- Possibility to use the filter for filling and draining of the system.

- Water absorbing filter can be integrated together with a particle element. In this way you will get a filter unit, which can absorb fine particles as well as condensed water.

An example of an off-line filter unit

Can Water in Oil Cause Damage to Hydraulic- and Lube Oil Systems?

Water is another very common source of contamination in oil systems. It attacks the system in the following ways:

- Metal is corroded.

- The oil is decomposed, additives are liberated, the oil is oxidized and the thickness of the lubricating film layer is reduced.

- Metal fatigue on the surfaces is precipitated.

- Components are blocked by ice crystals being formed at low temperatures.

- Wear of hydraulic components is precipitated.

Are you aware that…

... the most important and at the same time the most neglected component in each hydraulic- and lube oil system is the oil? Decomposition of the oil causes loss of essential components in the oil. Decreasing lubricating qualities accelerates wear and thus causes in-creased generation of particles.

Water might cause liberation of the additives and consequently the formation of acids and sludge, which can block nozzles, form a layer on the surface of the components and heat exchangers, block filters and apart form precipitate wear. Water should be removed from oil in order to obtain the longest possible life of oil and components.

The damage caused by corrosion is well-known. Corrosion arises because of the presence of acid and free water in the oil. The formation of acid can be strongly reduced by removing the water. If rust stains or corroded holes are observed, or if the surfaces of bearings or other metal components are quickly corroding, there are every probability of the existence of free water in the system. Contamination with water may cause such problems and may after relatively short time result in weakened metal surfaces, which are destroyed by the subsequent contact loads under normal operation.

Did you know…

…many years of experience in the Danish industry have demonstrated that the majority (60-80 %) of all operational interruptions on hydraulic- and lube oil systems are caused, directly or indirectly, by impurities in the oil? This goes for energy, maritime and industrial enterprises. Common for them all are that interruptions of operations means loss of production.

Determination of Water in Oil

- and how to eliminate it?

If, when taking out a routine oil sample, the oil is unclear, it is very probable that there is water in the oil. If the oil sample looks like thin milk there is no doubt about the presence of water in the oil.

IKM Ocean Team is able to determine the percentage of water in your oil with use of Karl Fischer Colorimetric Titration. This method is characterized by:

- A very specific and precise measurement method for determination of water.

- Covers a wide concentration area from only a few ppm and up to 100% of water.

- A quick method – you will receive the results within only one day.

The most common recommendation in connection with determination of too high levels of water in oil is changing the oil in your system. However, this is not an easy job, as you will often find it impossible to dismantle all components in a system in order to drain them.

The most common recommendation in connection with determination of too high levels of water in oil is changing the oil in your system. However, this is not an easy job, as you will often find it impossible to dismantle all components in a system in order to drain them.

Moreover, the total volume of the system will usually have to be changed several times before the remains of the watery oil are completely out of the system. This is an uneconomic solution and a strain on the environment as well.

An alternative to the replacement of the oil can be to centrifuge or to 'boil' the water out of the oil by means of vacuum, while the system remains in operation. This can be done by installing a “dehydration system” through an offline circuit connected to the tank/reservoir of the system.

IKM Ocean Team’s Mobile Purifier cleans hydraulic- and lube oil by removing water, dirt and gases. It can be permanently installed or used as a mobile unit and is easy to operate and economic in use.

Benefits by Implementing 'Total Purity'

Implementation of “Total Purity” in your systems does not need to be a costly affair. It all starts with a correct training and instruction of your employees together with ensuring the right attitude toward purity.

It has been proven that the benefits of keeping a clean hydraulic- and lube oil system are:

- More efficient operation.

- Higher reliability and stability of the system.

- Improved lifetime of system components.

- Minimization of breakdowns and other system failures.

- Optimization of the repair and maintenance processes followed by reduced total costs.

IKM Ocean Team

- Your Reliable Partner in 'Total Purity' Solutions

IKM Ocean Team is specialized in implementation of 'Total Purity' in various technical systems. Our many years of experience has giving us a unique knowledge about purity in technical systems. This makes us capable of assisting you in all processes within this matter, involving:

- Initial consultancy and trouble shooting.

- Training and instruction within 'Total Purity'.

- Development of customized purification units.

- Total cleaning of your systems.

- Control and monitoring of contamination level.