Eliminate and prevent varnish formation without any system shutdown with IKM Ocean Team's newly developed and patented method

Once varnish deposits generate in your system, it can be very difficult to eliminate. We therefore focus on eliminating the catalysts to varnish in order to prevent the formation process from starting.

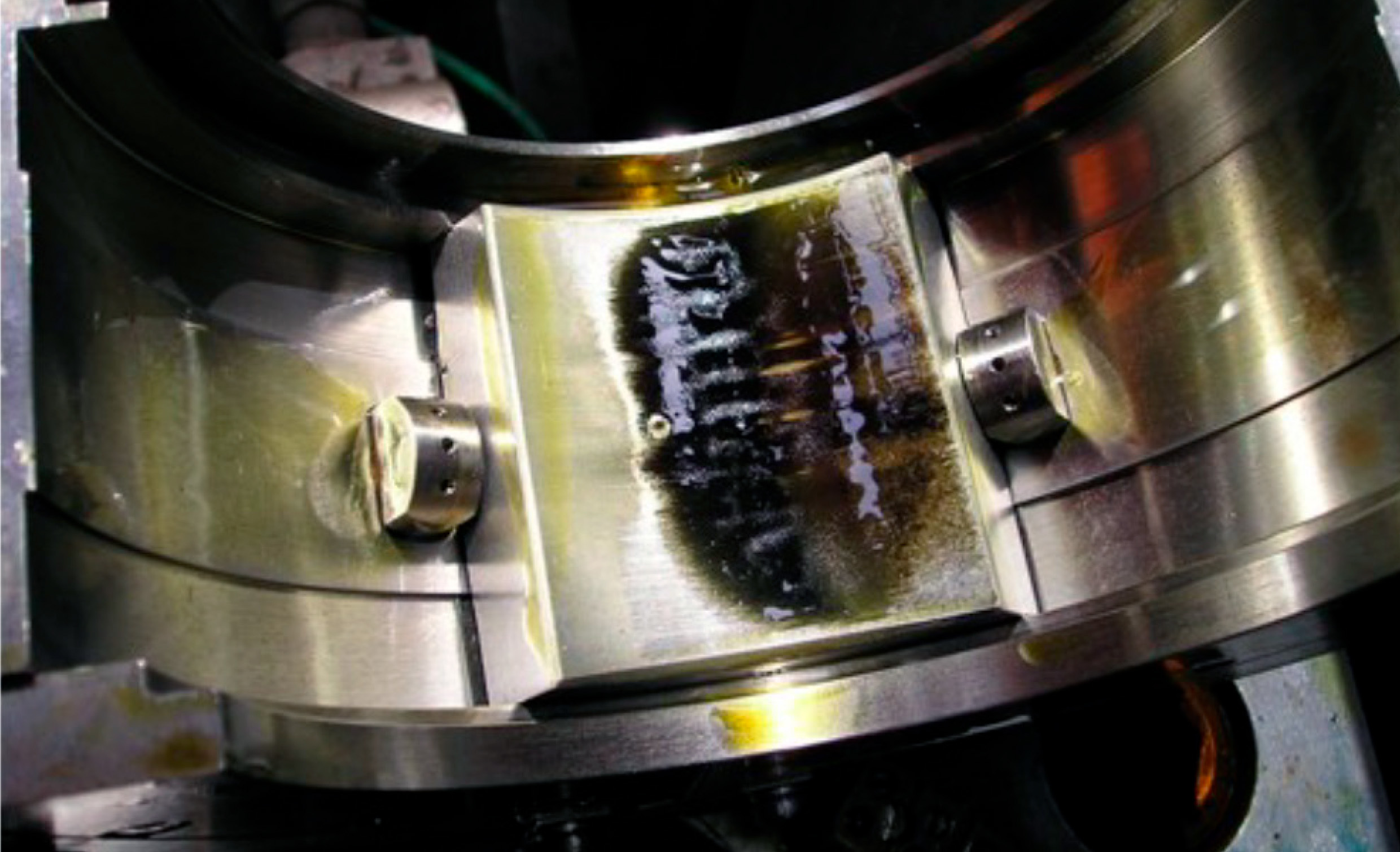

Example of the consequences of varnish deposits.

Remove All Catalysts in ONE Step

In only ONE single step, our unit is able to remove all known catalysts to varnish including:

- Foreign substances - internal and external particles in the oil

- Moisture - water mixed in the oil

- Gases and air bubbles

- Possible varnish formation

Example of dissolved varnish in the process of in-depth oil condtioning.

Remarkable Benefits

IKM Ocean Team's “In-depth Oil Conditioner” represents a new way of thinking degassing and dehydration of oil giving some remarkable benefits:

- Online cleaning = No production loss - no shutdown of the infected system during cleaning, saves expensive production loss.

- ATEX approved system - the method is approved for operation in potentially explosive atmospheres.

- High flow capacity - a capacity of more than 150 litres/minute ensures a fast cleaning of medium and large-sized oil systems.

- Longer lifetime of the oil - cleaning the oil rather than changing it, saves cost and is positive for the environment.

“Varnish is Your System’s Toughest Enemy”

Eliminate and prevent varnish formation. It can be difficult, yet in order to prevent varnish, eliminate the catalysts.