Contamination and leaks are not the only problems you may encounter with hydraulic fluids, however, varnish, caused by oxidation, can cause downtime, and in worst-case scenarios, catastrophic failure of a system.

As a compliment to oil flushing, IKM Ocean Team has implemented ISOPur in our range of service performances and have become certified representative of ISOPur products.

Grows Sub-Micron Particles into larger Particles!

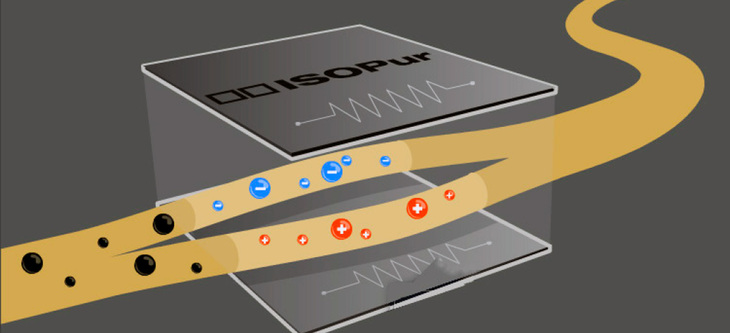

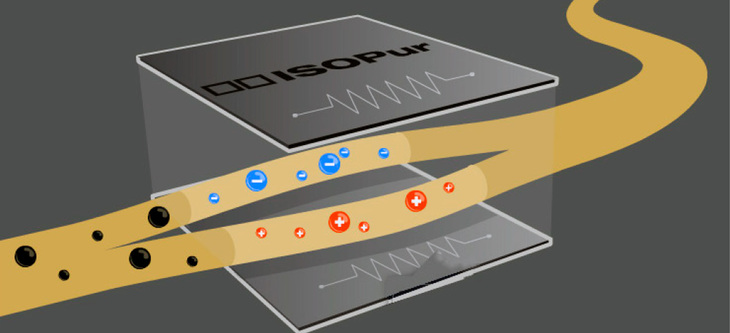

The ISOPur charging and mixing unit splits fluid flow into two paths, with the particles in each path being charged electrostatically by positive and negative electrodes.

These opposite charged particles attract and agglomerate, and then these larger particles are removed by the filtering system.

How ISOPur Patented Balanced Charge Agglomeration technology works:

- Passing contaminated fluid over a series of electrodes that carefully charge particles, both positive (+) and negative (-).

- Particulate contamination as small as 0.1 microns picks up this charge.

- Oil, a non-conducting fluid, stays neutral.

- The ionized fluid streams are then re-combined and mixed under turbulent flow.

- Positively and negatively ionized contaminant particles are attracted to each other, growing in size as they agglomerate.

- Sub-micron particles become micron-sized particles. Micron-sized particles become multi-micron particles, etc.

- Once larger, these particles are then easily removed by standard filtration.

“BCATM technology makes filters work better”

ISOPur’s patented Balanced Charge Agglomeration (BCATM) technology grows sub-micron particles into larger particles, which improves existing filter performance.

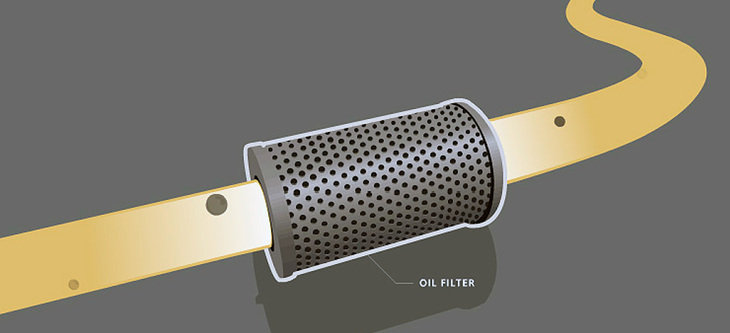

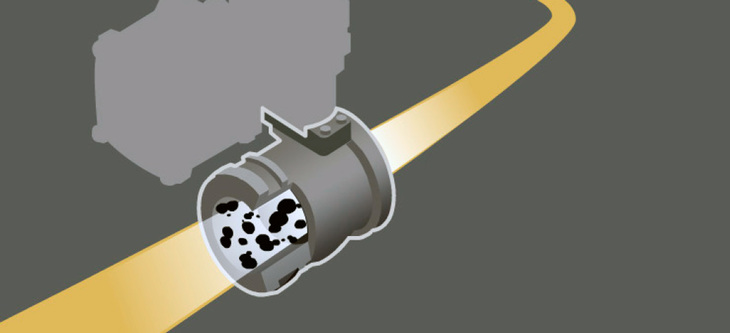

Mechanical Filtration

- Currently, lubrication contamination is controlled by mechanical filters that have remained virtually unchanged for the last 50 years.

- These filters can remove large particles but are ineffective on highly adhesive and abrasive particles in the 0.1 to 5.0 micron range.

- These small particles are highly polar and are precursors of sludge and varnish build-up on machine internals.

- Eventually, they cause grinding, adhesion, and component failure.

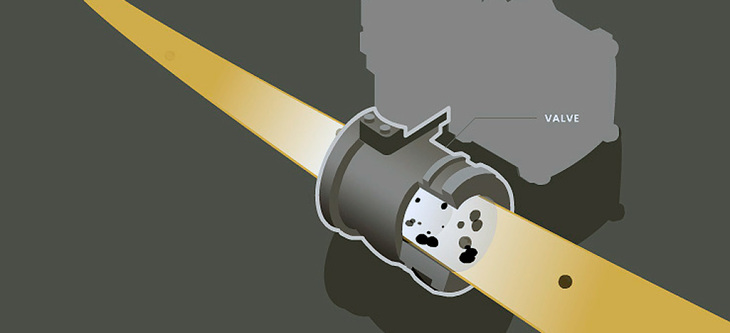

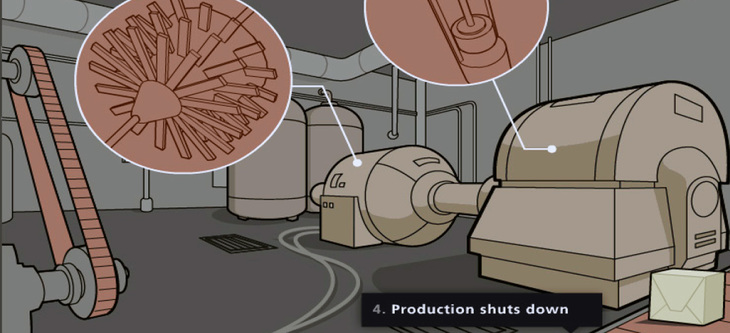

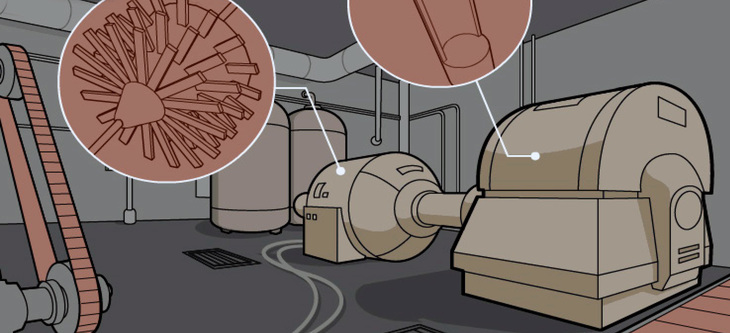

Problems

- Sludge and varnish build-up

- Grinding bearings and shafts

- Sticking hydraulic valves

- Production shuts down

“IKM Ocean Team - ISOPur Representative”

As a compliment to oil flushing, IKM Ocean Team has now implemented ISOPur in our range of service performances and have become a certified representative of ISOPur.

Balanced Change Purification

- ISOPur’s patented Balanced Change Purification (BCP) technology works by passing contaminated fluid over a series of electrodes that carefully charge particles, both positive and negative.

- When the net charge of the fluid is balanced, the particles attract and grow in size.

Contaminant particles, including sub-micron particles, are now large enough to be easily removed by ISOPur’s collection filter.

Fluid lubricity is maintained, additives remain untouched, and water content is reduced.

- By balancing the net charge of the fluid, BCP eliminates polar molecules that cause sludge and varnish.

- Mission critical equipment is continuously maintained in pristine condition.

Treatable Fluids

- Lubricating oil

- Hydraulic oil

- Phosphate ester machining oil

- Diesel fuel

- Vegetable oil

- EDM fluid

- Dielectric fluids

- Turbine oil

- Any non-conducting fluids

Keep your machinery clean with ISOPur.

Benefits

- Higher product yield

- Reduced maintenance

- Increased uptime

- Longer equipment life

Experience the Power of Purity

Significant Return on Investment

ISOPur save on operation, maintenance, and production costs that add up to a rapid and quantifiable return on investment:

- Production downtime reduced

- Production yields improved

- Unplanned maintenance reduced

- Teardown/maintenance schedules extended

- Flushing services eliminated

- Oil disposal reduced

- Oil replacement reduced