In the month of June, onshore, in the temperate climate belt. The wind farm turbine oil degraded severely showing vast volumes of varnish covering the full system. We value our client’s trust showing us the extreme case. However, it was not the first of its type that we recognized.

State of the Turbines

Customer changed oil every three months. The oil degraded too fast. Some turbines operated using a Mobil gear oil type. One other turbine did not make it: the gear system was exchanged fully.

At arrival, the system condition was assessed as critical.

Oxidated Oil

- We assumed because of oxidation, as such cases were encountered before at other customers. Oxidation generates from old oil and from chemical reactions when left without proper oil flushing. Proper flushing includes turbulent flow conditions during the oil change. The risk arises when remaining oxidation sludge is not entirely flushed out of the system before adding new oil. Cross contamination causes the remaining oil to create oxidation sludge attacking the additive package of the new oil. Consequently, even during the first months, a very fast degradation of the new oil begins.

Life Extension

Life extension of oil, a main target for the wind industry, has consequences as presented by this case, and as anticipated when not altering any other preconditions. As varnish problems were expected, IKM Ocean Team developed a technical method to improve a needed flushing procedure.

Up-Tower Gear Box Flushing

The method is easy to use during ordinary oil change. The technology is named ‘Up-tower Gear Box Flushing’. The technique integrates induced waves to obtain turbulent flow conditions for, during pulsation, gently to tear oxidation products from surfaces in gears, tubes, hoses, components and coolers. The ‘Up-tower’ flushing technology combines turbulent flow rates with added vibrations.

Consequently, coatings release pieces to the oil, becoming filterable by depth- or special filters. Due to the vast oil volume pumped, all parts of the gearbox are impacted and treated.

Scope of Work

Project scope includes to rid gearbox of oxidation deposits and sludge off surfaces in the gearbox and in the associated lubrication system. This is obtained by using a combination of a varnish remover oil and the ‘Up-Tower Gearbox Flushing’ technology, purifying oil systems of severe degradation residues. Removing oxidation deposits, oil life-time is optimized significantly compared to earlier used oil change methods.

Varnish Remover Solvent

The varnish remover oil is a solvent, added to the oil obtaining an improved solvent power and carrying capacity purifying the oxidation sludge found in the system. The purpose of the additive is to dissolve and transport as much oxidation residue as possible back into the oil in the shortest possible time. The product does not hold any negative effect to the permanent lubrication oil in the system, minimizing the risk of catalyzing a quicker breakdown of the base oil qualities. Any oil additive must be carefully chosen as the oil’s ability to separate water is under increased risk as well as that of precipitation of the EP additive.

Up-Tower Flushing Avails Life Extension

Basically, varnish settles on polar surfaces, i.e. noble metals, and on cooled surfaces below 40 degrees Celsius. Effectively, the cooling system surface is deposited with a layer of varnish impacting the cooling effect. For example, 0.5 mm of varnish decrease the effect by up to 40-50%.

This again impacts the general life-time of the oil, generically minimizing the oil’s life-time by 50% at a temperature increase of 10 degrees Celsius.

Furthermore, oxidation residues settle on precious materials, often corrosive to the settling metals. Release of cupper in the oil, combined with water causes the oil to degrade faster. Using ‘Up-tower’ flushing, all surfaces in the system are impacted contributing to the desired result adding to life extensions compared to earlier used oil change methods.

Test Description

WTG power output: 2MW

WTG oil volume: 450 liters

Gear oil type: ISO VG 320

Arriving, during and after the ‘Up-Tower Flushing’ representative oil samples are taken by defined intervals and methods to illustrate the effect of the process. Samples document the performance of the IKM Ocean Team purification method compared to the customary oil change.

Test Results

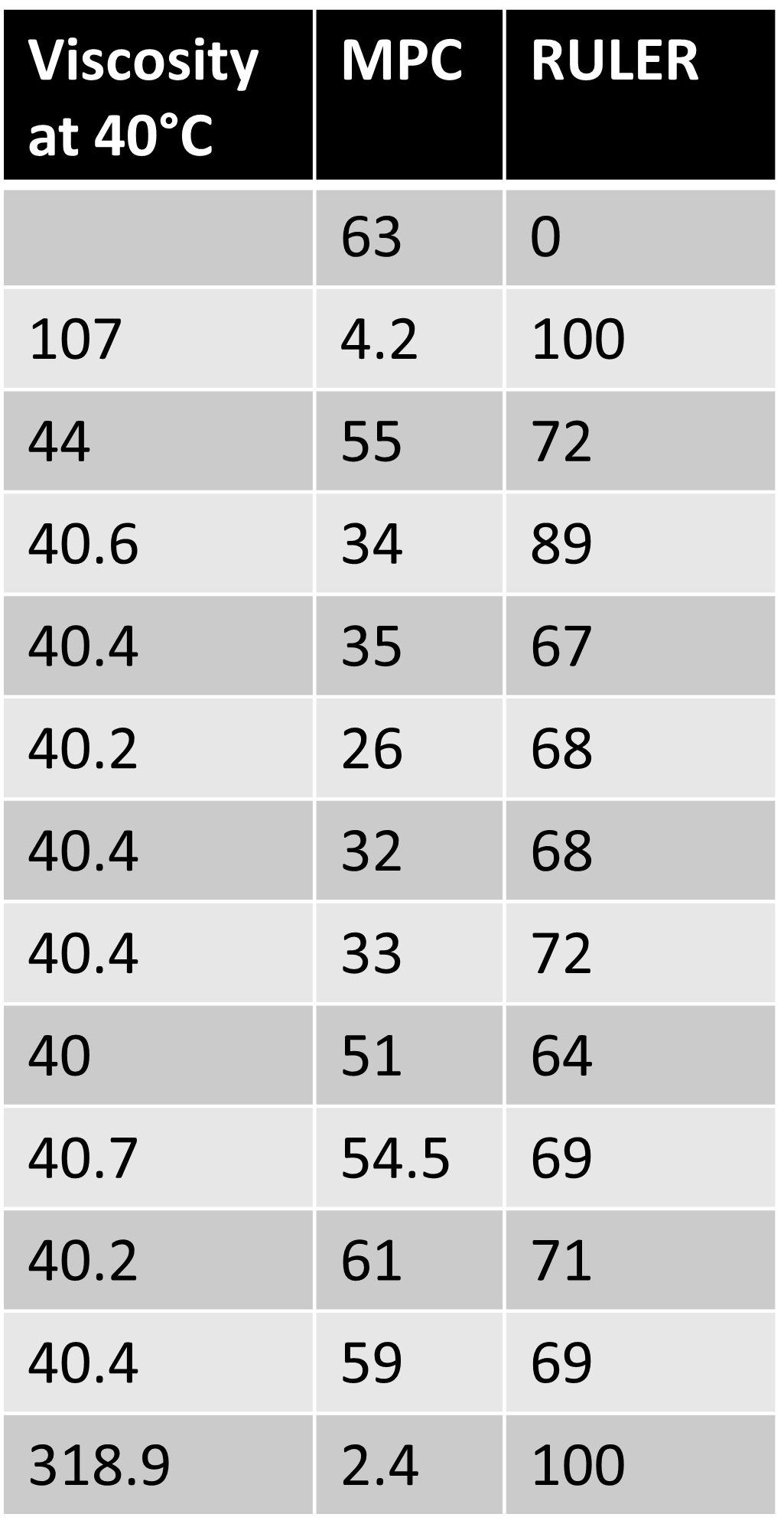

The following preconditions are measured starting the ‘Up-Tower Flushing’ process, tests having been performed on a qualified third-party oil laboratory:

MPC measurements were taken to follow the development during a process where varnish was released into the new oil to be filtered.

At the beginning an exemplary test:

11:15 The new flushing oil were measured to 4.2 dE. This figure is used as reference measure to this test. The viscosity is measured to 107.5 mm2/s at 40 degrees Celsius, indicating that the equipment used for filling the oil have not been emptied. A mix with another oil type must be anticipated.

The TAN figure is measured to 0.49 mg KOH/g.

The cupper figure is measured to 0.4 mg/kg.

Analysis Conclusion

Based on generated results, the following conclusions applies: Successful flushing is proved by comparing system conditions documented by photos from arrival to site and from the time of departure. Major visual coatings are reduced considerately. The system oxidation is removed, and the samples indicates a stable acid number. The purpose was to remove oxidation residues and sub-micron particles deposited in the system, obtained by dissolving these with a, for the new

oil, safe product. The used products in combination are considered risk free and will not damage the gear oil product properties separating water or other chemical deposits.

Industry Conclusion

Once a wind turbine operator decides the gear oil is at the end of its useful life, 'filling-for-life' preconditions a thorough drainage of the system; an up-tower flushing to eliminate risk of contamination from the previous oil fill, refilling of oil and extending the life-time of the new oil further, using additives. Initially, having reached a very clean system, ‘filling-for-life’ is possible by backfilling of additives only. The above-mentioned flushing procedure addresses deposits and varnish, and hence allows wind turbine operating companies to evidence their commitment to sustainable and environmentally sound practices.