IKM Ocean Team’s Contamination Monitoring Program provides an extensive analysis of the hydraulic and lubricating oil system. It is thus possible to check the capacity of the system by excluding important factors of contamination, which might cause decomposition or disastrous system faults.

Reliable samples are the base for accurate laboratory results.

Cleanliness of the oil sampling method is of critical importance for the accuracy of the laboratory results. If a sample is falsely contaminated by taking it from the wrong point or in the wrong way, or if the sampling equipment or method introduces contamination, inaccurate contamination levels will be reported. Reliable samples are those that are cleanly taken from the circulating oil flow according to ISO 4021 and ISO 3722. IKM Ocean Team’s engineers are highly trained and qualified in this field and can help you secure representative oil samples.

The cleanliness or purity of a lubricant is determined by the count of solid particles in a 100 ml. sample of the fluid. The cleanliness class code is defined by the number of particles of different sizes pr. ml. of sample fluid. The ISO 4406 (1999) standard describes the electronic laser particles count as well as the coding of the cleanliness class for lubricants. In ISO 4406 (1999), three scale numbers are used to describe solids contamination: 4 µm and larger, 6 µm and larger and 14 µm and larger.

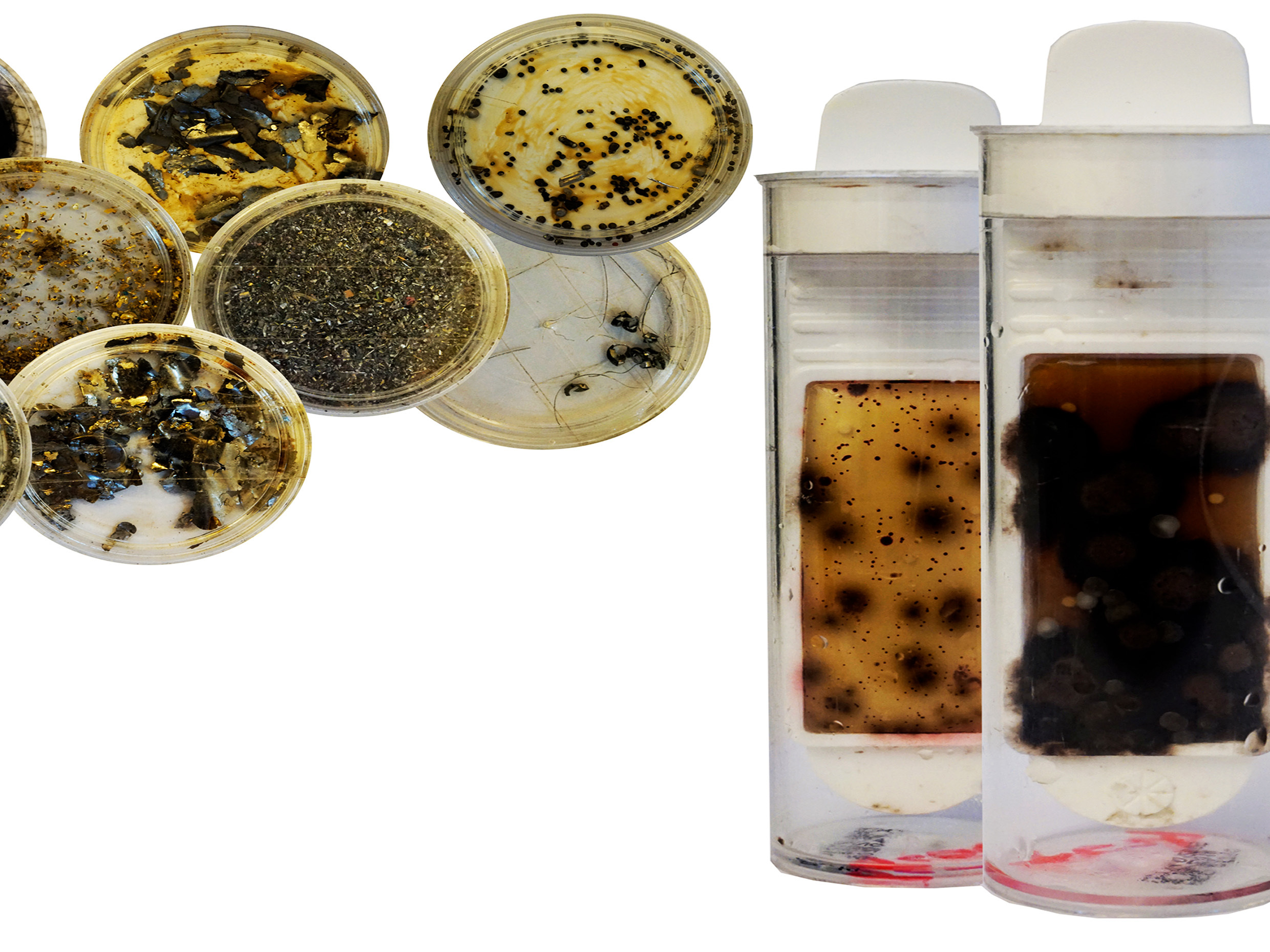

System wear and original source of contamination are identified by analysis components.

Knowledge of the type of contamination can be of great help in diagnosing system wear. If particles of specific metals are present, it is often possible to identify the decomposing components and perhaps the original source of the contamination. According to ISO 4407, part of the oil sample should be filtered through an analysis membrane and analysed by means of an optical microscope to determine the type of contamination (by an on-the-spot check). All contaminating particles classified and measured between 5 µm and 15 µm are evaluated and categorised as bright metal, black metal, brass, silicon, elastomer or plastic, fibre, etc. The number and size of the particles are evaluated visually and compared to photos, master slides, or other comparison guides for various purity classes, identified according to ISO 4407 class or directly convertible from Nas 1638 class. IKM Ocean Team’s engineers are highly trained and qualified in particle identification, and can provide a full diagnosis, including advice and suggested action plan for achieving improvements.

In addition, IKM Ocean Team may assist you take representative oil samples and send them to an independent laboratory for full-spectrum analysis. The laboratory can measure a large range of parameters and factors that influence oil quality. Typically these include tests that quantify:

- The number and size of particles.

- The types and quantity of contamination present.

- The changes in oil chemistry caused by the operating environment.

- The amount of water present.

- The TAN value.

- The viscosity of the oil.

Final result is a comprehensive report, which can help you decide future measures in case of problems. Additional analyses can be made at regular intervals to ensure the effectiveness of the measures taken and to give advance warning of any approaching faults in the machinery.

This service also provides assurance that the system is safe to operate.

IKM Ocean Team offers full technical support and references for contamination monitoring programs. Our skilled engineers and state-of-the-art equipment are ready to provide such services at your request.

View Trend, Health Check and Monitoring Program flyer

View On-site Oil Analysis Program flyer

View Service Description for The Analytical Content of the Contamination Monitoring Program