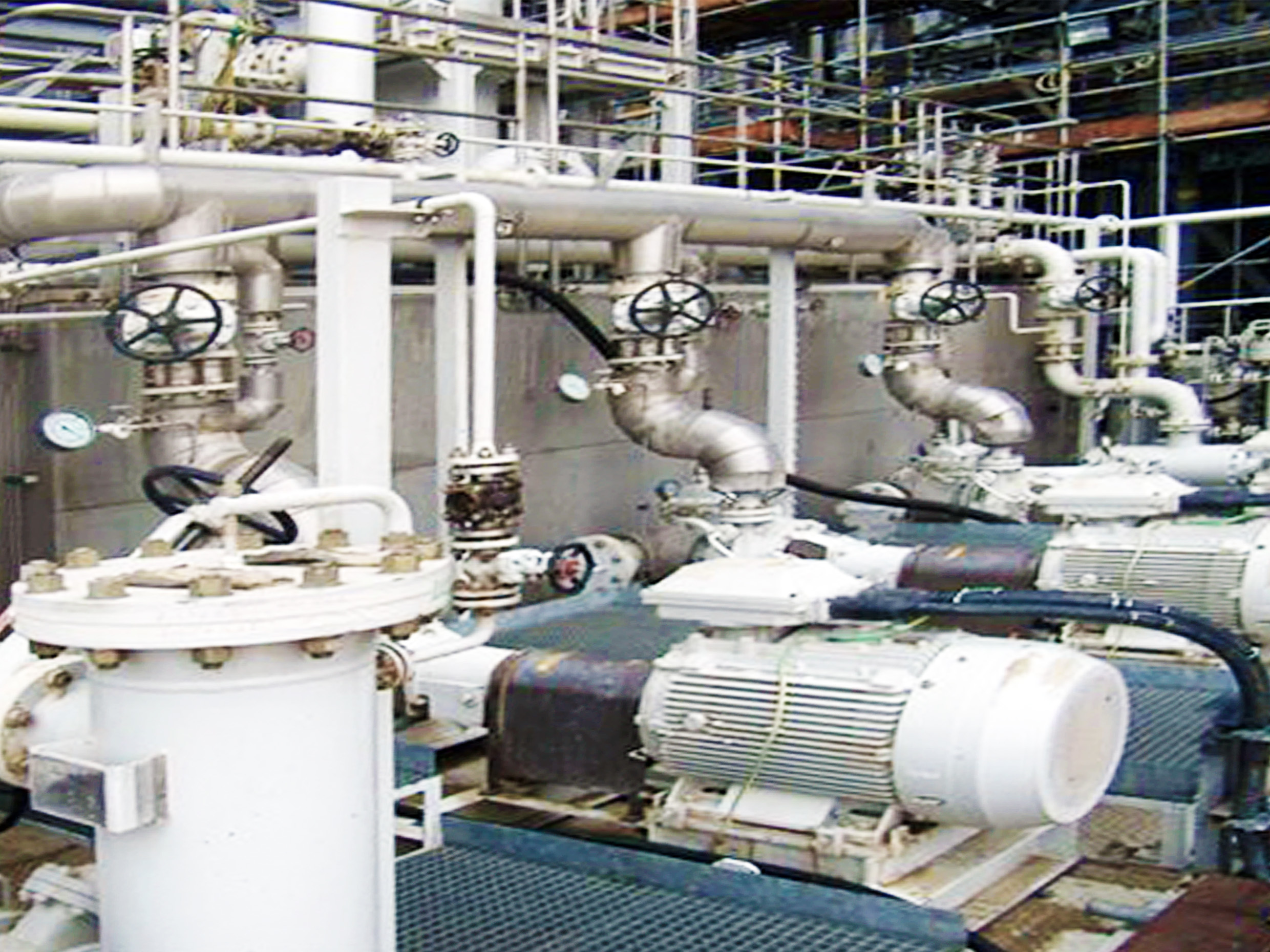

Besides using conventional oil flushing methods for turbine and compressor lubricating oil systems, IKM Ocean Team has developed a number of significant improvements to the flushing process, reducing flushing time and increasing cleanliness level. One method is to expose the flushing oil to pulses, caused by sudden and controlled compression, in order to create sound waves (induced waves) and an even higher Reynold number in the pipe system. The resulting turbulent flow and sound waves dislodge impurities on the insides of a pipe system or cooler and flush them with the oil to the filters. Another possibility is to create vibration inside the system, rather than outside, along with the flow of oil, a method which greatly enhances the cleaning process, especially in oil coolers. The use of thermal shocks also enhances system efficiency.

IKM Ocean Team has experiences with turbine lube oil flushing Worldwide.

A side benefit of the successfully completed flushing is that it eliminates the need to replace the old turbine/compressor oil or to dispose of it, thus saving considerable expenses and benefitting the environment. In addition, it gives you peace of mind in knowing that you have an extremely clean system and extremely clean oil.

The improvement of the conventional flushing process is a perfect example of IKM Ocean Team always developing new methods for better results to the benefit of our customers.